Success by Design

We have skilled design engineers on staff here at Caltronics who together represent a cumulative 45 years with the company, and with that tenure comes a breadth of experience. Detailed below are some projects they appreciated working on, and an explanation of what Caltronics Design & Assembly has accomplished in the past.

New Tech on the Surface Mount Assembly Line

Maintenance versus New Equipment

It’s a scenario as old as machine-assisted manufacturing itself: an existing functioning-for-now piece of equipment is now an older model and the possibility of increasingly costly repairs is becoming higher and higher so you investigate whether acquiring a newer model now is more beneficial, or if waiting a little longer could give you an edge. Our most recent iteration of this scenario resulted in the former option, and thus new opportunities have emerged.

Caltronics’ Industry Certifications, Compliances, and Memberships

Manufacturing certifications to Caltronics represent a stamp of professionalism within the industry. It is an outward communication of our values and the commitment we make daily to deliver a quality product. This blog post will cover the various certifications and compliances we maintain.

Big Changes to Electromechanical Assembly at Caltronics!

Big Changes have come to Caltronics Design & Assembly via some improvements within the electromechanical assembly department, bringing it up to a level that can handle increasing demand while still upholding the standards we promise you.

Maintaining Quality Objectives Through 2021

Manufacturers have been facing reduced supply, inflated prices, and increased lead times since the beginning of 2021. Unfortunately, forecasts show that these conditions will continue to persist in at least some fashion for the remainder of the year.

Caltronics Design & Assembly’s New Year’s Resolution

Every year January 1st brings a rejuvenating feeling that many individuals rely on as a source of motivation to start driving the new year on a better foot than they left the last. This rejuvenation feels more important than ever as 2021 starts with folks having quite literally survived 2020 and all its never-before-seen challenges.

Minnesota-Based Manufacturing Servicing Minnesota and Beyond

National or local business partners? A decades old question that has seen the rise and fall of both sides of the argument several times over. The basis of the argument as it stands now is simple: outsource and save money on labor and parts or support local businesses possibly at your budget’s expense.

Caltronics Design & Assembly Recently Partnered With Bell Bank

Caltronics Design & Assembly recently partnered with Bell Bank for some of our loans. We have been grateful to have them as amazing partners even before the pandemic. When it came to our PPP loan we had found our banking partner frustrating and difficult to work with as they were not proactive in helping us secure our funding. When we turned to Bell Bank, they were able to get us approved quickly and we know we an count on them moving forward! Chad and his team there do excellent work and we are proud to have them as our bank.

Ensuring Quality PCB Inspections in the Face of a Growing Emphasis on Speed

Serving as an essential business during the widespread shutdowns earlier this year, we continue to be grateful for the opportunity to operate with adaptations in place so that we might serve our customers while maintaining the utmost safety for our employees. We at Caltronics have taken pride in our ability to prioritize the highest quality in our PCB and PCBA products despite the added hurdles of this year, and we have our quality practices to thank for that.

Your American PCB Manufacturer and Assembly Company

Businesses are facing new and unexpected challenges seemingly every day. What companies once accepted as dependable resources or partnerships are no longer upholding the same standard. Companies are being forced to navigate new ways to obtain the products or services that they need in order to carry out their business.

We Answer the 10 Common PCB Design and Assembly Questions Asked by Clients

We Answer the 10 Common PCB Design and Assembly Questions Asked by Clients We have compiled a list of 10 common questions we receive from clients before starting their design projects.

Caltronics Prototyping and Engineering Design Process

Caltronics Prototyping and Engineering Design Process We often partner with engineers and clients who have identified a problem that needs to be fixed or they have an idea for a new product. They come to us and explain what they are looking for.

PCB profitability with Design for Test (DFT)

Design for test/testing/testability. Design for manufacture. Design for assembly. Design for…well, you get the picture. There are a lot of “design for’s” to keep in mind. But they all boil down to one concept: design for profitability.

That’s especially important when considering PCB design for test (DFT). PCBs can be complex, and they’re expected to work without errors. Inspection and testing are essential to PCB manufacturing but can be time-consuming and costly.

How can you accommodate inspection and testing requirements and keep a product profitable?

Five win-win reasons for leaning out your PCBA and electronics assembly

It’s a good bet your electronic product requires more than a printed circuit board assembly (PCBA). Components such as wires, actuators, controls, displays, potting and even an enclosure likely need electronics assembly. Plus you may need product labeling, instruction manuals, shelf packaging and so on.

Caltronics donation aims to build student interest

With a plan to build a relationship with local schools to help the students understand that manufacturing encompasses many different jobs, Caltronics Design and Assembly, Inc. designed and built a printed circuit board to donate to the high school electronics class.

PCB Design: Design for Manufacturability

Prior planning prevents poor performance, they say. With PCBs, effective planning involves Design for Manufacture and Assembly (DFMA). That means thinking past the “sky’s the limit” PCB-design phase to consider the realities of putting a product together.

DFMA principles focus on creating an efficient manufacturing process that lowers production costs.

The secret to PCB perfection (shhh, it’s inspection and testing)

The electronics business is made up of serious perfectionists whose basic assumption is that devices will perform flawlessly time after time. But perfection is hard to come by.

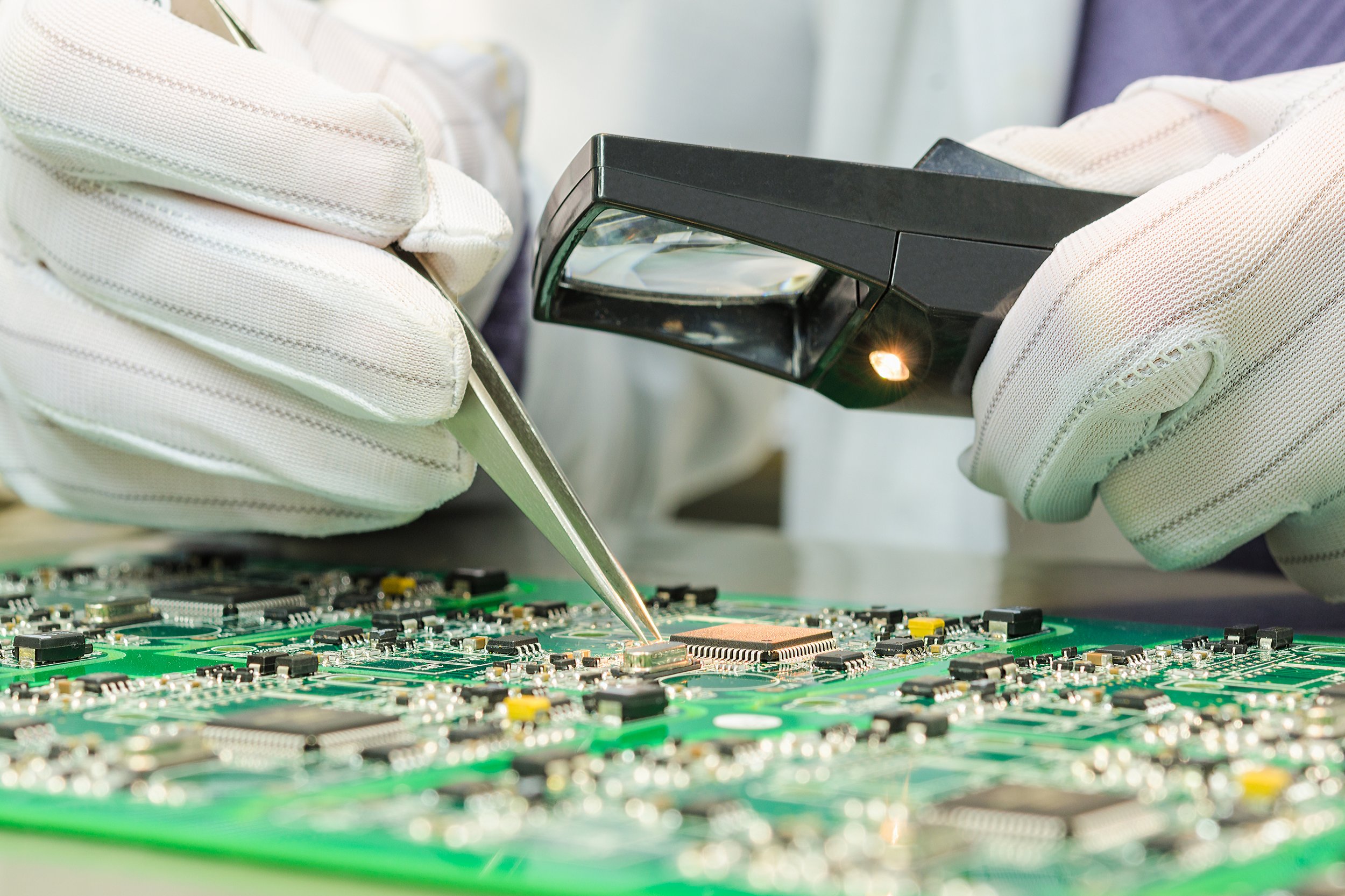

In the real world, a printed circuit board’s many components and solder joints must meet design specifications exactly for the PCB to function properly. To ensure perfection, inspection is a critical part of PCB fabrication.

What PCB inspection methodologies are there? Which ones will work best for your project? All you need to know is in our white paper.

Solder jet printing: What you need to know for SMT Printed Circuit Board outsourcing

Solder jet printing: What you need to know for SMT Printed Circuit Board outsourcing “More good boards, faster.” That’s the basic reason for using solder jet printing. Since solder quality is a major factor in SMT board defects, high-quality solder jet printing can play a major role in striking the balance between throughput.

3-D AOI: A new dimension in PCB inspection

3-D AOI: A new dimension in PCB inspection Move over, 2-D automated optical inspection (AOI). There’s a new kid on the block when it comes to PCB inspection. Introducing 3-D AOI. With the growing use of surface mount technology (SMT) and chip packages like ball grid arrays (BGAs), solder connection planarity issues come up that call

PCB inspection: Taking it to the next level with X-ray

PCB inspection: Taking it to the next level with X-ray No one thinks it’s OK for a diagnostic device to just stop working. Or for flight instruments to conk out. Dependent on complex PCBs for their smarts, these devices have to be 100%, 24/7 reliable.