Ensuring Quality PCB Inspections in the Face of a Growing Emphasis on Speed

Serving as an essential business during the widespread shutdowns earlier this year, we continue to be grateful for the opportunity to operate with adaptations in place so that we might serve our customers while maintaining the utmost safety for our employees. We at Caltronics have taken pride in our ability to prioritize the highest quality in our PCB and PCBA products despite the added hurdles of this year, and we have our quality practices to thank for that.

Accomplishing Quality Products

Caltronics has been able to accomplish quality products time and time again due to this emphasis on efficiency, especially where PCB Testing is concerned. We hold our products to rigid PCB Inspection Standards so we can be confident that when we ship out a product it is functioning as intended and packaged in adequate ESD safe materials for the safest shipping. That all starts at the beginning, when we order our bare boards from one of our US based suppliers and have them test the bare boards for compliance with industry and customer-specific requirements.

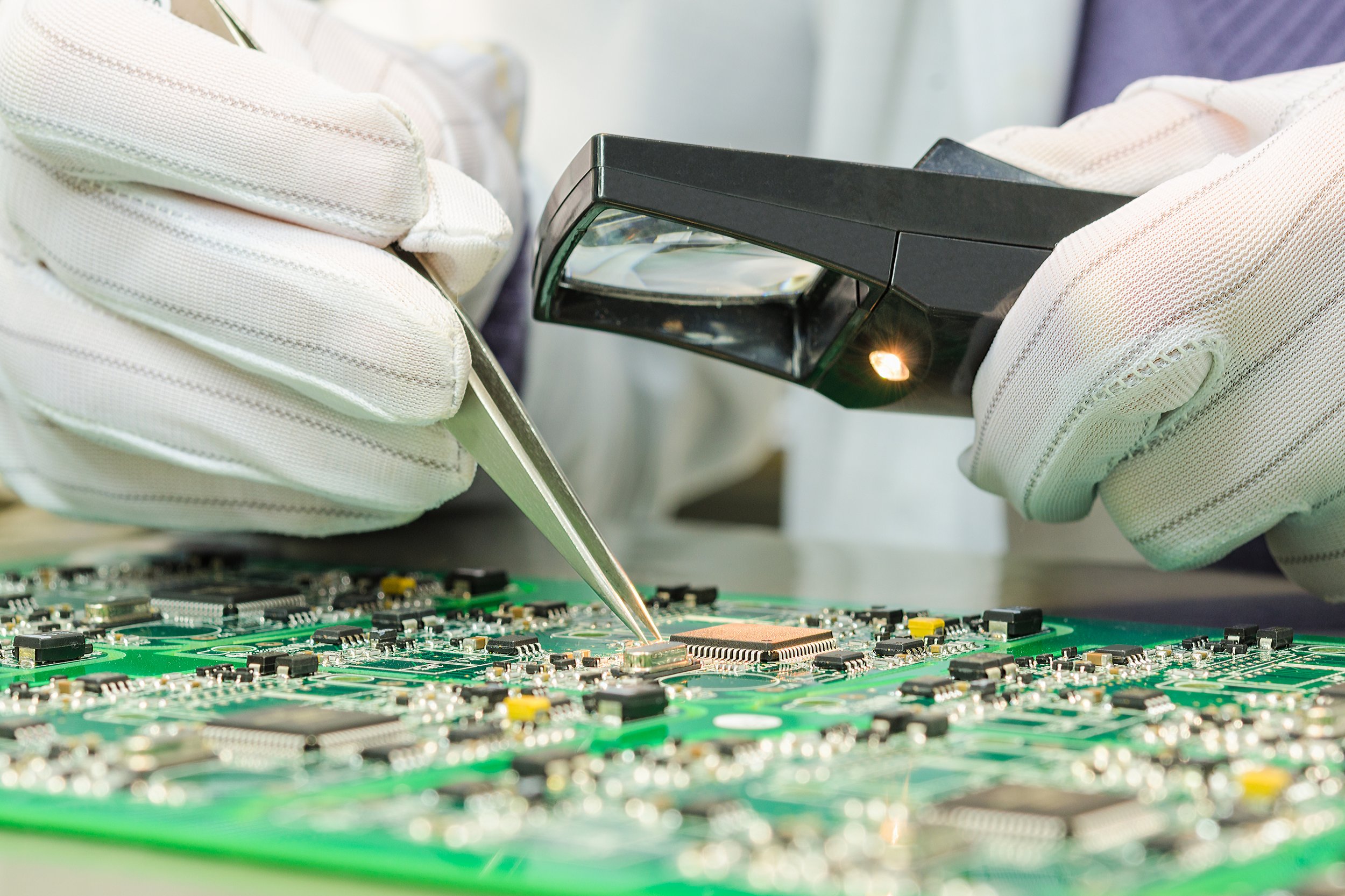

Once they reach us and the assembly process begins, we continue to be thorough by having our IPC certified electrical and mechanical assemblers, along with giving them the tools needed to assist them and increase the efficiency of their inspections. Machines like our Automated Optical Inspection (AOI) and X-Ray devices are the tools that allow our assemblers to perform inspection tasks more efficiently when Visual Inspection leaves room for doubt.

Return Material Authorization Process

Caltronics believes in a realistic approach to business because pretending nonconformances will never happen is nowhere as viable as having plans to address them, so we also have processes in place to address the times when a product fails to meet product specifications or when our testing and inspection steps reveal an issue. Our rework and returned material authorization (RMA) processes aim to ensure a fast, efficient fix so that we can get a functioning product into your hands within a time frame that works for everyone.