Big Changes to Electromechanical Assembly at Caltronics!

Big Changes have come to Caltronics Design & Assembly via some improvements within the electromechanical assembly department, bringing it up to a level that can handle increasing demand while still upholding the standards we promise you.

Caltronics Design & Assembly’s New Year’s Resolution

Every year January 1st brings a rejuvenating feeling that many individuals rely on as a source of motivation to start driving the new year on a better foot than they left the last. This rejuvenation feels more important than ever as 2021 starts with folks having quite literally survived 2020 and all its never-before-seen challenges.

Minnesota-Based Manufacturing Servicing Minnesota and Beyond

National or local business partners? A decades old question that has seen the rise and fall of both sides of the argument several times over. The basis of the argument as it stands now is simple: outsource and save money on labor and parts or support local businesses possibly at your budget’s expense.

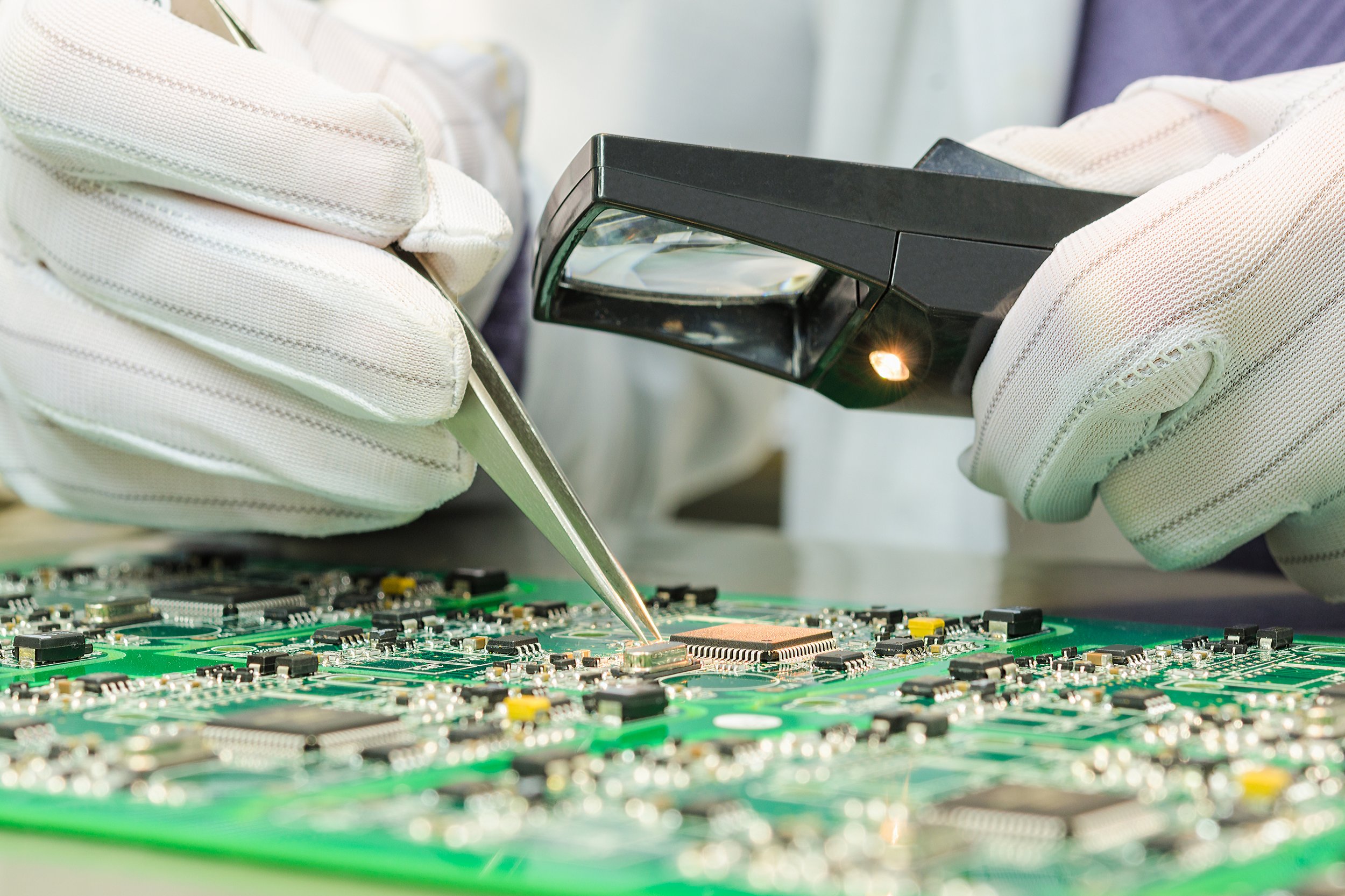

Ensuring Quality PCB Inspections in the Face of a Growing Emphasis on Speed

Serving as an essential business during the widespread shutdowns earlier this year, we continue to be grateful for the opportunity to operate with adaptations in place so that we might serve our customers while maintaining the utmost safety for our employees. We at Caltronics have taken pride in our ability to prioritize the highest quality in our PCB and PCBA products despite the added hurdles of this year, and we have our quality practices to thank for that.

Five win-win reasons for leaning out your PCBA and electronics assembly

It’s a good bet your electronic product requires more than a printed circuit board assembly (PCBA). Components such as wires, actuators, controls, displays, potting and even an enclosure likely need electronics assembly. Plus you may need product labeling, instruction manuals, shelf packaging and so on.