PCB Reverse Engineering

PCB Reverse Engineering Service: Unlock, Analyze, and Improve Your Existing Designs

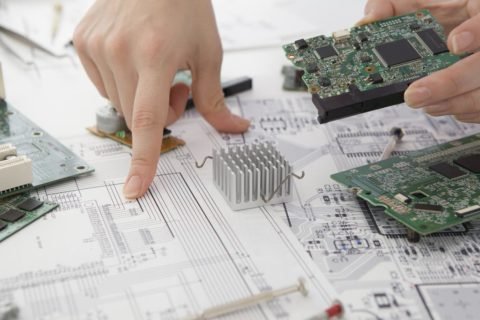

Caltronics PCB reverse engineering service offers precise and reliable solutions for analyzing, reproducing, and improving existing circuit board designs. Whether you need to replicate an obsolete board, enhance functionality, or troubleshoot an unknown design, our PCB reverse engineering service provides the expertise to bring your ideas to life.

What is PCB Reverse Engineering?

PCB Reverse Engineering is the process of deconstructing a circuit board to extract its schematic, component placement, and design details. This service is invaluable for businesses looking to:

Reproduce outdated or discontinued PCBs

Improve or modify existing board designs

Recover lost design files

Verify or troubleshoot an existing circuit board design

Our Comprehensive Reverse Engineering Process

Our PCB Reverse Engineering Service follows a meticulous process to ensure accuracy and efficiency:

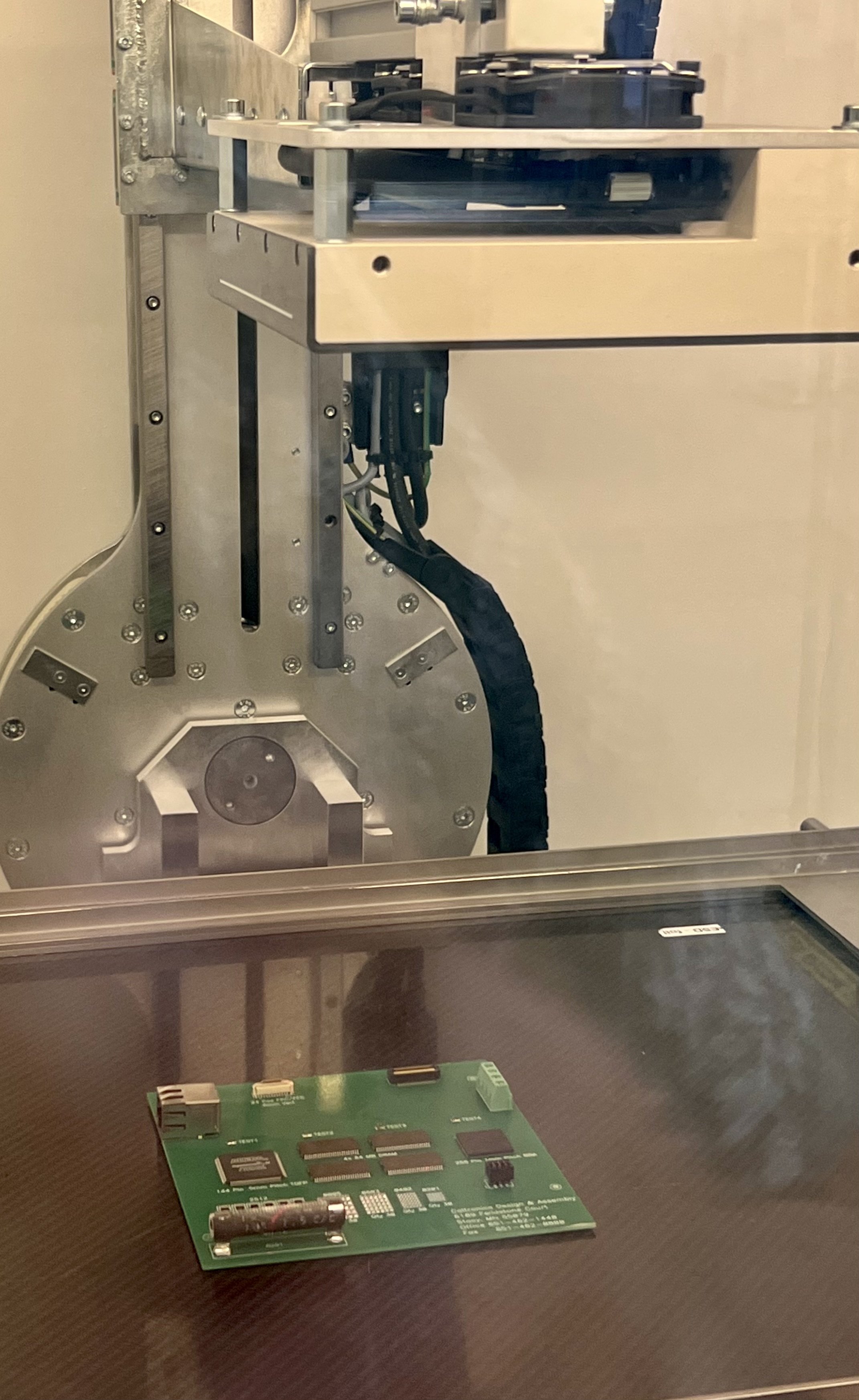

1. Board Analysis & Component Identification

We begin by inspecting the PCB using multi-angle X-ray and 3D optical inspection to map out component placement, trace layouts, and layer structures.

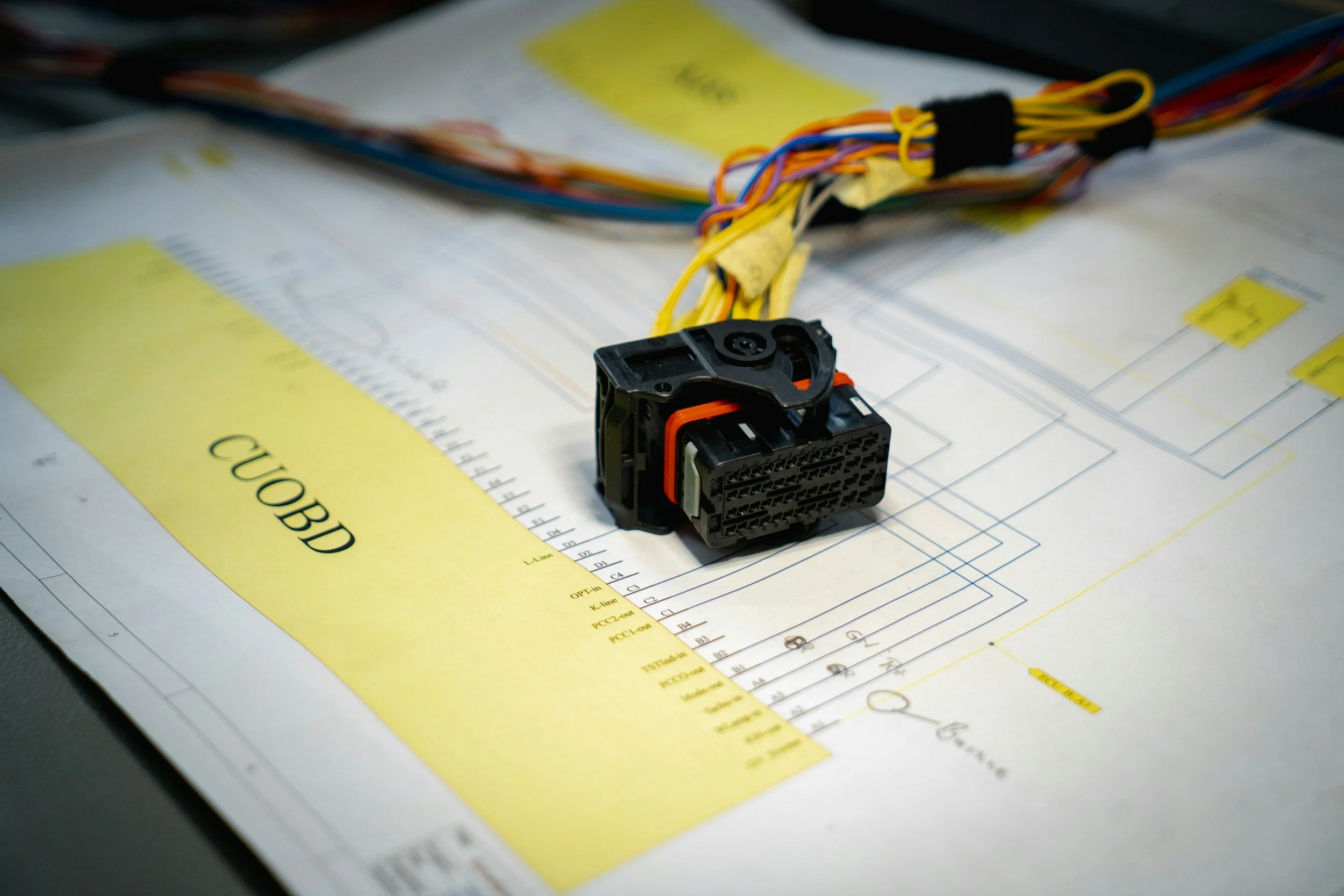

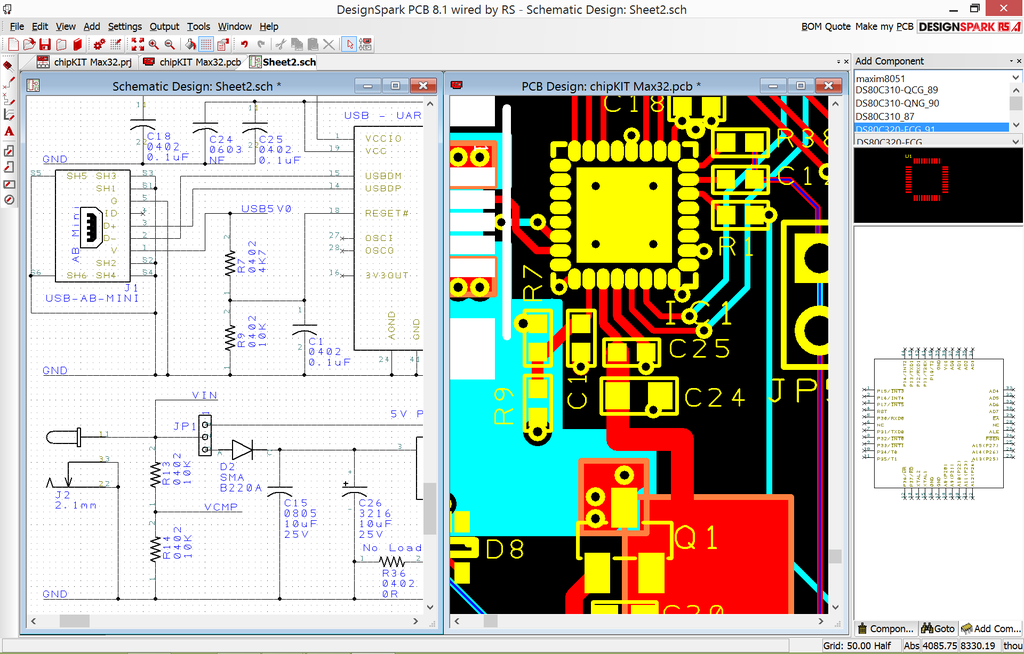

2. Schematic Extraction

Using CAD tools, we extract the original schematic from the PCB, ensuring component values, traces, and interconnections are accurately documented.

3. Bill of Materials (BOM) Reconstruction

We identify and catalog all components, sourcing equivalent or alternative parts if necessary, especially for obsolete or hard-to-find items.

4. PCB Layout Recreation

Our engineers recreate the PCB layout, ensuring it matches or improves upon the original board.

5. Prototyping & Testing

Before full-scale production, we fabricate a prototype for testing, ensuring functionality and compliance with your requirements and industry standards.

Markets We Serve

Why Choose Caltronics for PCB Reverse Engineering?

Expertise in Complex PCBs – From simple single-layer boards to complex multi-layer designs, we reverse-engineer with precision.

Full Scale Technology – Equipped with multi-angle X-ray inspection, 3D Automated Optical Inspection (AOI), and environmental testing, we ensure the highest level of accuracy.

Full-Service Support – From schematic recovery to manufacturing, we offer end-to-end PCB solutions.

ISO 9001 Certified & ITAR Registered – We adhere to strict quality control and security standards.

Quick Turnaround – Whether you need rapid prototyping or full-scale production, we deliver efficient results.

Get Started with Caltronics Today

Ready to turn your innovative ideas into reality? Fill out the form below or call us at 651.462.1440 to learn how we can assist you in achieving your goals.

Related Services