Caltronics Design & Assembly’s New Year’s Resolution

Every year January 1st brings a rejuvenating feeling that many individuals rely on as a source of motivation to start driving the new year on a better foot than they left the last. This rejuvenation feels more important than ever as 2021 starts with folks having quite literally survived 2020 and all its never-before-seen challenges.

Minnesota-Based Manufacturing Servicing Minnesota and Beyond

National or local business partners? A decades old question that has seen the rise and fall of both sides of the argument several times over. The basis of the argument as it stands now is simple: outsource and save money on labor and parts or support local businesses possibly at your budget’s expense.

Ensuring Quality PCB Inspections in the Face of a Growing Emphasis on Speed

Serving as an essential business during the widespread shutdowns earlier this year, we continue to be grateful for the opportunity to operate with adaptations in place so that we might serve our customers while maintaining the utmost safety for our employees. We at Caltronics have taken pride in our ability to prioritize the highest quality in our PCB and PCBA products despite the added hurdles of this year, and we have our quality practices to thank for that.

Your American PCB Manufacturer and Assembly Company

Businesses are facing new and unexpected challenges seemingly every day. What companies once accepted as dependable resources or partnerships are no longer upholding the same standard. Companies are being forced to navigate new ways to obtain the products or services that they need in order to carry out their business.

PCB profitability with Design for Test (DFT)

Design for test/testing/testability. Design for manufacture. Design for assembly. Design for…well, you get the picture. There are a lot of “design for’s” to keep in mind. But they all boil down to one concept: design for profitability.

That’s especially important when considering PCB design for test (DFT). PCBs can be complex, and they’re expected to work without errors. Inspection and testing are essential to PCB manufacturing but can be time-consuming and costly.

How can you accommodate inspection and testing requirements and keep a product profitable?

PCB Design: Design for Manufacturability

Prior planning prevents poor performance, they say. With PCBs, effective planning involves Design for Manufacture and Assembly (DFMA). That means thinking past the “sky’s the limit” PCB-design phase to consider the realities of putting a product together.

DFMA principles focus on creating an efficient manufacturing process that lowers production costs.

The secret to PCB perfection (shhh, it’s inspection and testing)

The electronics business is made up of serious perfectionists whose basic assumption is that devices will perform flawlessly time after time. But perfection is hard to come by.

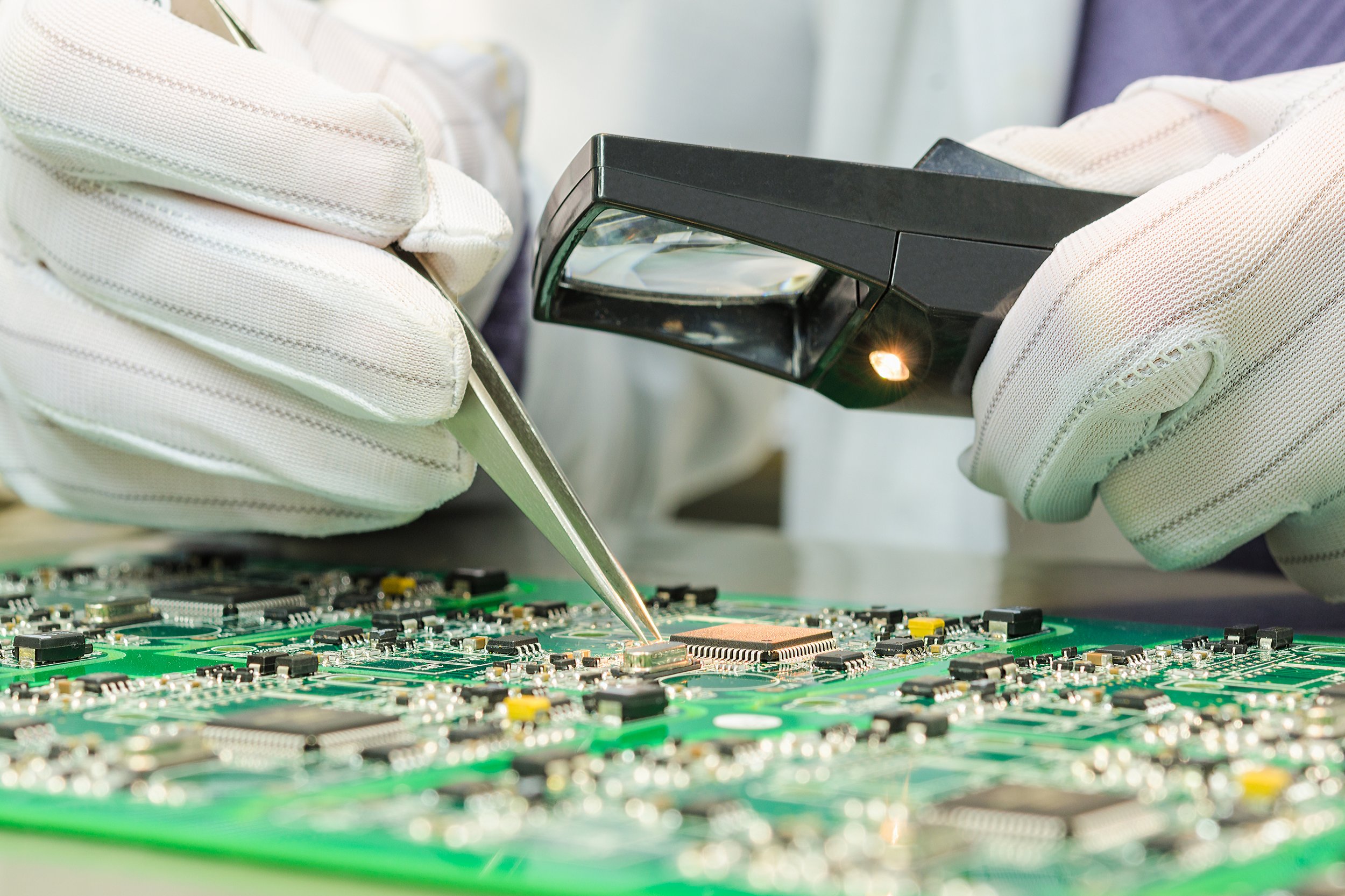

In the real world, a printed circuit board’s many components and solder joints must meet design specifications exactly for the PCB to function properly. To ensure perfection, inspection is a critical part of PCB fabrication.

What PCB inspection methodologies are there? Which ones will work best for your project? All you need to know is in our white paper.

Get What You want from Your PCB Team

At Caltronics we have found the importance of communicating clearly with our clients to make sure the product they receive accomplishes what they need and want it to do. That’s why our PCB teams are so important to us and our clients.

How do I Improve My Design?

How do I Improve My Design? At Caltronics, we have been a part of many interesting designs and projects. Sometimes these prove to be great lessons for us that we carry into new work. One of those lessons we learned is about optimizing a project for our clients.