Success by Design

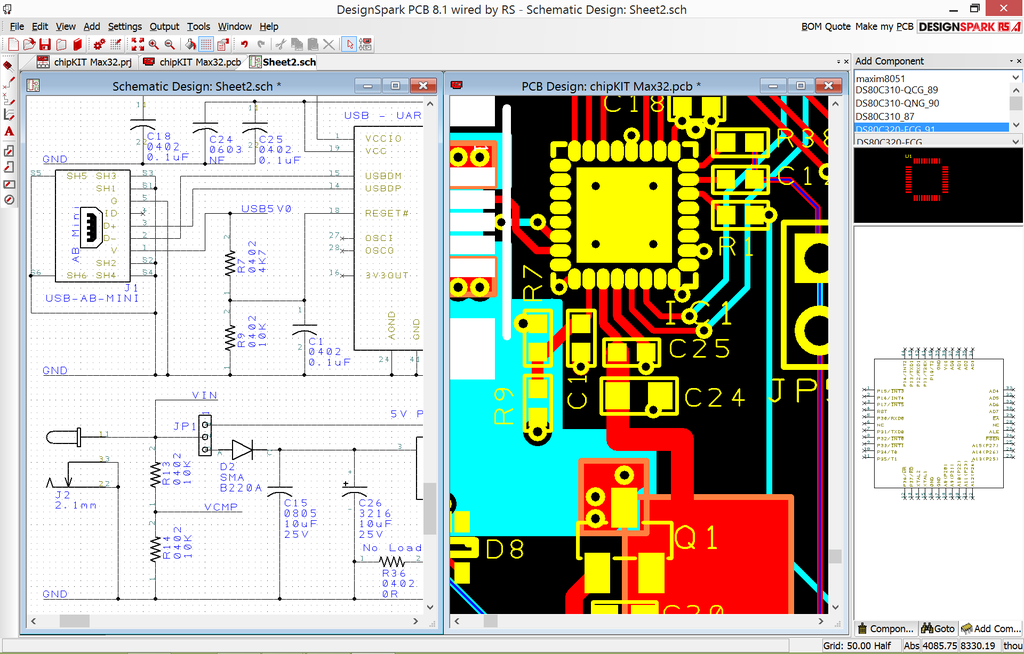

PCB and circuit design software screenshot.

The Design Team

We have skilled design engineers on staff here at Caltronics who together represent a cumulative 45 years with the company, and with that tenure comes a breadth of experience. Detailed below are some projects they appreciated working on, and an explanation of what Caltronics Design & Assembly has accomplished in the past.

The Projects

Our Lead Design Engineer loves a challenge and the pride in his work that comes with complete design projects. When we refer to a project as complete we are talking about a project where the team must undertake circuit design, the layout of the board, program firmware and software should the project need it, any integration with other devices, and finally any final housing or assembly a client might be looking for. Even when a project doesn’t entail all those steps though the pace of the work and the positive feedback from customers makes every project a rewarding one. For a recent example for which he served as the main engineer see the following:

The project (called for) the design and layout of an amplifier board that was designed to take in 3 sensor readings from 25 different battery cells (75 total sensor readings) and amplify them. The 3 readings were for Voltage, Temperature, and Current. The Voltage reading was just a straight pass-through on the board with no amplification. The Temperature reading was amplified using a precise formula to maximize the Temperature signal gain, getting the best resolution possible. The Current reading was passed through an adjustable low pass filter (to remove high frequency noise) and an adjustable and highly precise instrumentation amplifier; the adjustability in both the filter (95Hz to 307kHz) and the amplifier (1x to 128x) gives the user maximum control over how the output signal is presented.

Another project our design team has appreciated for its complexity and unique challenges and how it allowed for thorough communication with the customer is recounted below. The team finds some of their most rewarding projects to be similar to the following example.

We did the design, layout, and assembly for this board. The customer previously used a commercial breakout board (Microchip RN41VXU-I/RM) on several of their products, but that product went obsolete. However, the main component on the board (Microchip RN41N-I/RM) will continue to be manufactured, so we were asked to replicate the breakout board. The original breakout board was very compact, so this project required precise measurement of the original board and careful tracing layout on the new board to accommodate the compact size.

Our Capabilities

Over the years the sheer number of projects Caltronics has seen has enabled us to build an extensive repertoire and ever-expand our capabilities both out on the production floor and in the design process. Some of the tasks our design team handles are shown above, but here is an expanded list:

Reverse engineering

BOM creation

Design for manufacturing

PCB layout design

Circuit design

Firmware

Software

Prototyping

Rev-up projects

Validation testing

The Caltronics Design & Assembly Promise

Our team of in-house design professionals aims to use their experience and knowledge to provide quality guidance and service no matter the project. Contact Caltronics through the website or call 651.462.1440 to get started on your electronics project. Together we’ll design and assemble something great!