Your American PCB Manufacturer and Assembly Company

Businesses are facing new and unexpected challenges seemingly every day. What companies once accepted as dependable resources or partnerships are no longer upholding the same standard. Companies are being forced to navigate new ways to obtain the products or services that they need in order to carry out their business.

We Answer the 10 Common PCB Design and Assembly Questions Asked by Clients

We Answer the 10 Common PCB Design and Assembly Questions Asked by Clients We have compiled a list of 10 common questions we receive from clients before starting their design projects.

Caltronics Prototyping and Engineering Design Process

Caltronics Prototyping and Engineering Design Process We often partner with engineers and clients who have identified a problem that needs to be fixed or they have an idea for a new product. They come to us and explain what they are looking for.

PCB profitability with Design for Test (DFT)

Design for test/testing/testability. Design for manufacture. Design for assembly. Design for…well, you get the picture. There are a lot of “design for’s” to keep in mind. But they all boil down to one concept: design for profitability.

That’s especially important when considering PCB design for test (DFT). PCBs can be complex, and they’re expected to work without errors. Inspection and testing are essential to PCB manufacturing but can be time-consuming and costly.

How can you accommodate inspection and testing requirements and keep a product profitable?

Five win-win reasons for leaning out your PCBA and electronics assembly

It’s a good bet your electronic product requires more than a printed circuit board assembly (PCBA). Components such as wires, actuators, controls, displays, potting and even an enclosure likely need electronics assembly. Plus you may need product labeling, instruction manuals, shelf packaging and so on.

PCB Design: Design for Manufacturability

Prior planning prevents poor performance, they say. With PCBs, effective planning involves Design for Manufacture and Assembly (DFMA). That means thinking past the “sky’s the limit” PCB-design phase to consider the realities of putting a product together.

DFMA principles focus on creating an efficient manufacturing process that lowers production costs.

The secret to PCB perfection (shhh, it’s inspection and testing)

The electronics business is made up of serious perfectionists whose basic assumption is that devices will perform flawlessly time after time. But perfection is hard to come by.

In the real world, a printed circuit board’s many components and solder joints must meet design specifications exactly for the PCB to function properly. To ensure perfection, inspection is a critical part of PCB fabrication.

What PCB inspection methodologies are there? Which ones will work best for your project? All you need to know is in our white paper.

PCB inspection: Taking it to the next level with X-ray

PCB inspection: Taking it to the next level with X-ray No one thinks it’s OK for a diagnostic device to just stop working. Or for flight instruments to conk out. Dependent on complex PCBs for their smarts, these devices have to be 100%, 24/7 reliable.

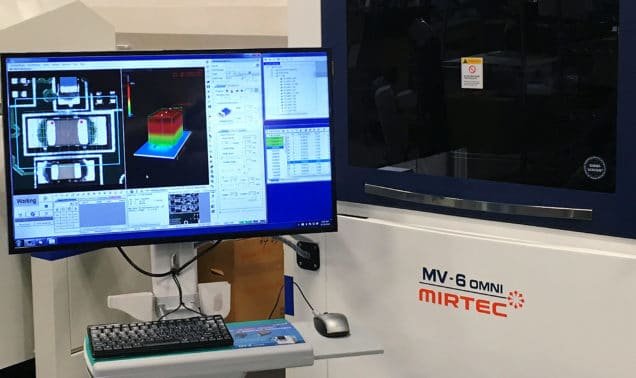

Caltronics purchases MIRTEC’s award-winning MV-6 OMNI 3-D AOI machine at SMTAI 2016

Caltronics purchases MIRTEC’s award-winning MV-6 OMNI 3-D AOI machine at SMTAI 2016 Caltronic’s own Cal Houdek, and Brian D’Amico, President of MIRTEC, at SMTAI 2016 Circuit Board Visual Inspections just got that much better with our newest addition, the MIRTEC MV-6 Automated Optical Inspection Machine. Caltronics is proud to announce our purchase of a MV-6 OMNI machine.

Solder Jet Printers!

Solder Jet Printers! You’ve spent months developing your newest product—a revolutionary medical device sure to transform the healthcare world. The mechanical parts are sourced, with other custom parts 3D printed for your first batch of prototypes. And you’ve brought on your electronics contract manufacturer to build 25 circuit boards for testing.

Get What You want from Your PCB Team

At Caltronics we have found the importance of communicating clearly with our clients to make sure the product they receive accomplishes what they need and want it to do. That’s why our PCB teams are so important to us and our clients.