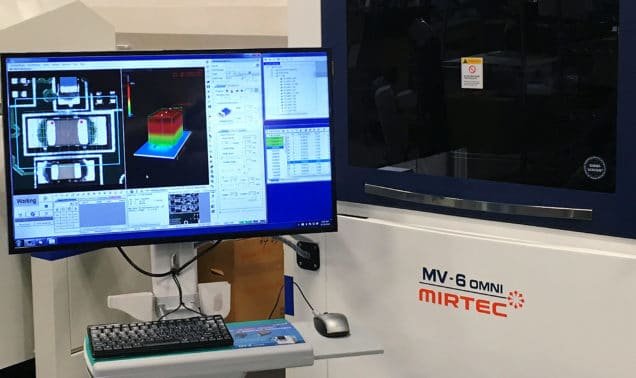

Caltronics purchases MIRTEC’s award-winning MV-6 OMNI 3-D AOI machine at SMTAI 2016

Circuit Board Visual Inspections just got that much better with our newest addition, the MIRTEC MV-6 Automated Optical Inspection Machine.

Caltronics is proud to announce our purchase of a new MIRTEC MV-6 Omni 3-D automated optical inspection (AOI) machine for PCBA inspection. Since purchasing our first MIRTEC AOI machine in 2008, Caltronics has seen the most common resistor sizes drop from 0805 to 0402 and other components have reduced in size as well.

Improving visual inspection was a key driver with the new machine’s 15-megapixel camera and 3-D system, Caltronics is equipped to provide excellent Printed Circuit Board Assembly (PCBA) quality control for device placement and soldering inspection well into the future.

The MV-6 has multiple inspection tools to help solve more issues than past inspection tools

Caltronics purchased the MV-6 ONI 3D AOI machine in order to improve the quality of their PCBs. There are two inspection tools on this AOI machine: 2D and 3D. The two-dimensional function of the machine helps by identifying missing components, incorrect components, components that are not aligned properly, polarity issues, tombstoning (when a component tilts up at one end), bridging (when too much solder is used and connects two or more pads), parts that are flipped and when there isn’t enough solder put on the board for the components it contains. The 3D aspect of the AOI machine helps with issues like the height of components, proper positioning of components when thermal issues cause pad lifting or insufficient solder.

Repairing Circuit boards before the final visual inspection helps quality and production time.

In purchasing the MIRTEC MV-6, Caltronics adds a computerized method to confirm quality in addition to the visual inspection we have been doing. Using the MIRTEC, the technicians no longer have to view the parts on circuit boards through microscopes and can view the images of the board and components on the board on an expanded computer screen, having the ability to zoom into known areas of concern or areas that the MIRTEC identifies as questionable. The technician can then repair the board before it goes to the final inspection.

To Learn More Contact Caltronics

We’re always improving our machines to help create a solution quicker, faster, and less expensive for you to take to market. If you’re looking to design or manufacture an electronic product we can help. We have the tools and talent to build and assemble your next project. Contact us or give us a call at 651.462.1440 today to get started!