Five win-win reasons for leaning out your PCBA and electronics assembly

It’s a good bet your electronic product requires more than a printed circuit board assembly (PCBA). Components such as wires, actuators, controls, displays, potting and even an enclosure likely need electronics assembly. Plus you may need product labeling, instruction manuals, shelf packaging and so on.

Caltronics donation aims to build student interest

With a plan to build a relationship with local schools to help the students understand that manufacturing encompasses many different jobs, Caltronics Design and Assembly, Inc. designed and built a printed circuit board to donate to the high school electronics class.

PCB Design: Design for Manufacturability

Prior planning prevents poor performance, they say. With PCBs, effective planning involves Design for Manufacture and Assembly (DFMA). That means thinking past the “sky’s the limit” PCB-design phase to consider the realities of putting a product together.

DFMA principles focus on creating an efficient manufacturing process that lowers production costs.

The secret to PCB perfection (shhh, it’s inspection and testing)

The electronics business is made up of serious perfectionists whose basic assumption is that devices will perform flawlessly time after time. But perfection is hard to come by.

In the real world, a printed circuit board’s many components and solder joints must meet design specifications exactly for the PCB to function properly. To ensure perfection, inspection is a critical part of PCB fabrication.

What PCB inspection methodologies are there? Which ones will work best for your project? All you need to know is in our white paper.

Solder jet printing: What you need to know for SMT Printed Circuit Board outsourcing

Solder jet printing: What you need to know for SMT Printed Circuit Board outsourcing “More good boards, faster.” That’s the basic reason for using solder jet printing. Since solder quality is a major factor in SMT board defects, high-quality solder jet printing can play a major role in striking the balance between throughput.

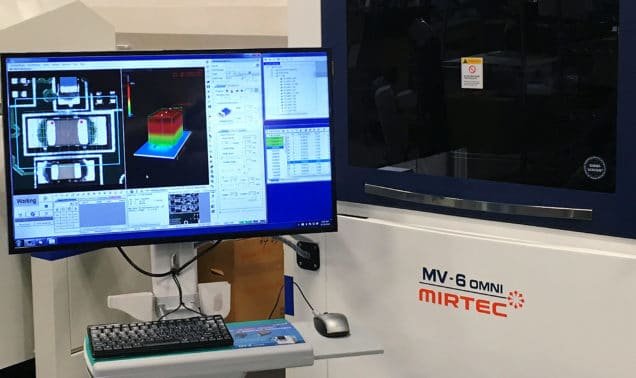

3-D AOI: A new dimension in PCB inspection

3-D AOI: A new dimension in PCB inspection Move over, 2-D automated optical inspection (AOI). There’s a new kid on the block when it comes to PCB inspection. Introducing 3-D AOI. With the growing use of surface mount technology (SMT) and chip packages like ball grid arrays (BGAs), solder connection planarity issues come up that call

PCB inspection: Taking it to the next level with X-ray

PCB inspection: Taking it to the next level with X-ray No one thinks it’s OK for a diagnostic device to just stop working. Or for flight instruments to conk out. Dependent on complex PCBs for their smarts, these devices have to be 100%, 24/7 reliable.

Caltronics purchases MIRTEC’s award-winning MV-6 OMNI 3-D AOI machine at SMTAI 2016

Caltronics purchases MIRTEC’s award-winning MV-6 OMNI 3-D AOI machine at SMTAI 2016 Caltronic’s own Cal Houdek, and Brian D’Amico, President of MIRTEC, at SMTAI 2016 Circuit Board Visual Inspections just got that much better with our newest addition, the MIRTEC MV-6 Automated Optical Inspection Machine. Caltronics is proud to announce our purchase of a MV-6 OMNI machine.

Caltronics Design & Assembly Receives ISO 9001 Certification: 2015

Caltronics Design & Assembly Receives ISO 9001 Certification: 2015 Caltronics Design & Assembly has received ISO 9001 certification for its quality management system after completing a rigorous certification process through ISO registrar, DEKRA. We engage in regular audits and our most recent audit was performed in July 2019.

Solder Jet Printers!

Solder Jet Printers! You’ve spent months developing your newest product—a revolutionary medical device sure to transform the healthcare world. The mechanical parts are sourced, with other custom parts 3D printed for your first batch of prototypes. And you’ve brought on your electronics contract manufacturer to build 25 circuit boards for testing.

Get What You want from Your PCB Team

At Caltronics we have found the importance of communicating clearly with our clients to make sure the product they receive accomplishes what they need and want it to do. That’s why our PCB teams are so important to us and our clients.

How do I Improve My Design?

How do I Improve My Design? At Caltronics, we have been a part of many interesting designs and projects. Sometimes these prove to be great lessons for us that we carry into new work. One of those lessons we learned is about optimizing a project for our clients.