PCBA Assembly Services

The Purpose and Reasoning for Printed Circuit Board Assembly Services (PCBA)

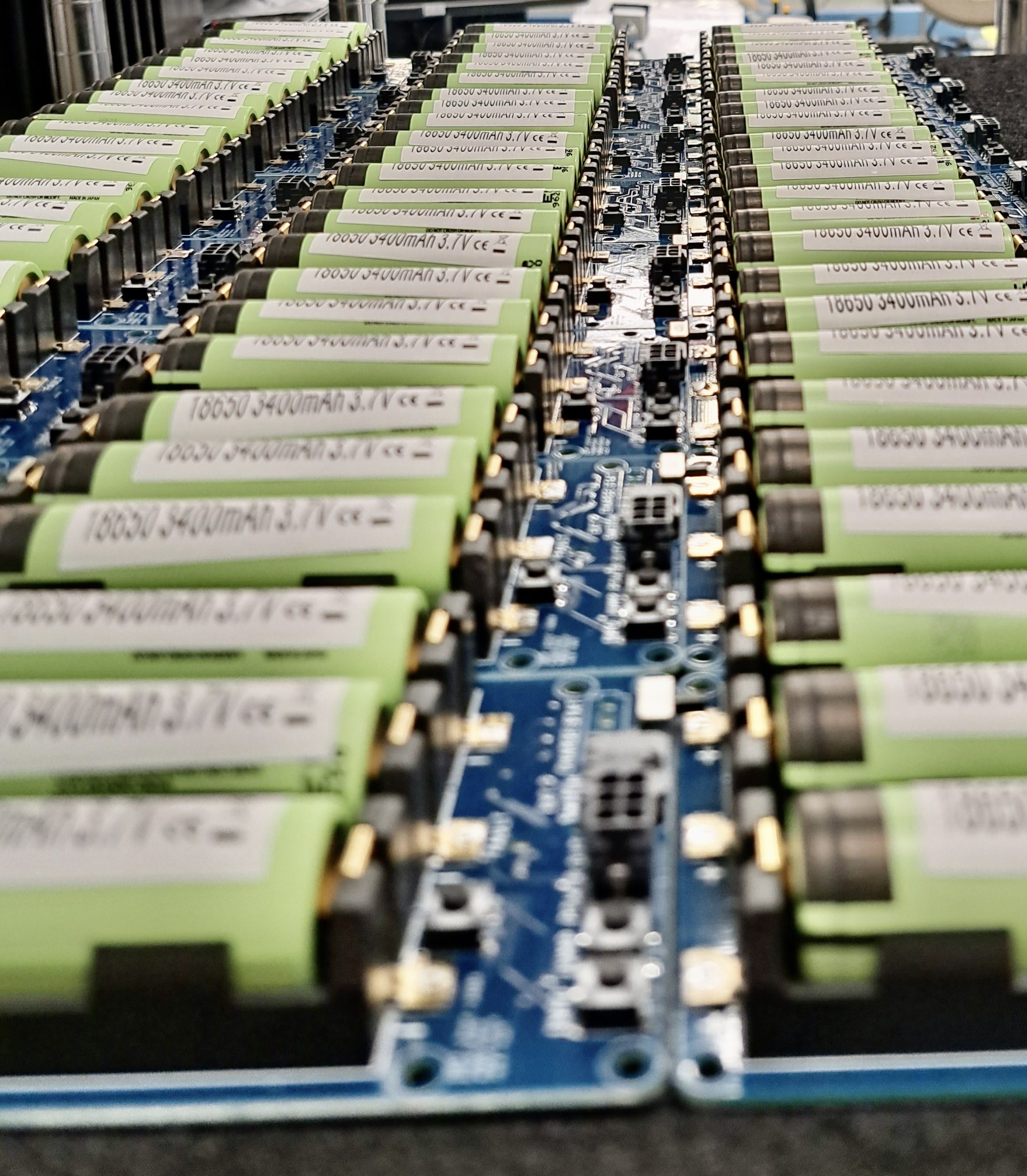

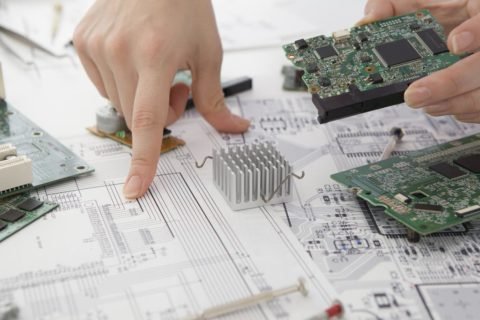

Caltronics’ in-house electrical and manufacturing engineers are skilled when it comes to printed circuit board assembly and ensure the PCBA you desire performs as needed. The engineers are available to consult during each phase of the PCBA manufacturing process to guide the products through assembly and production.

High-Quality PCB Assembly Services

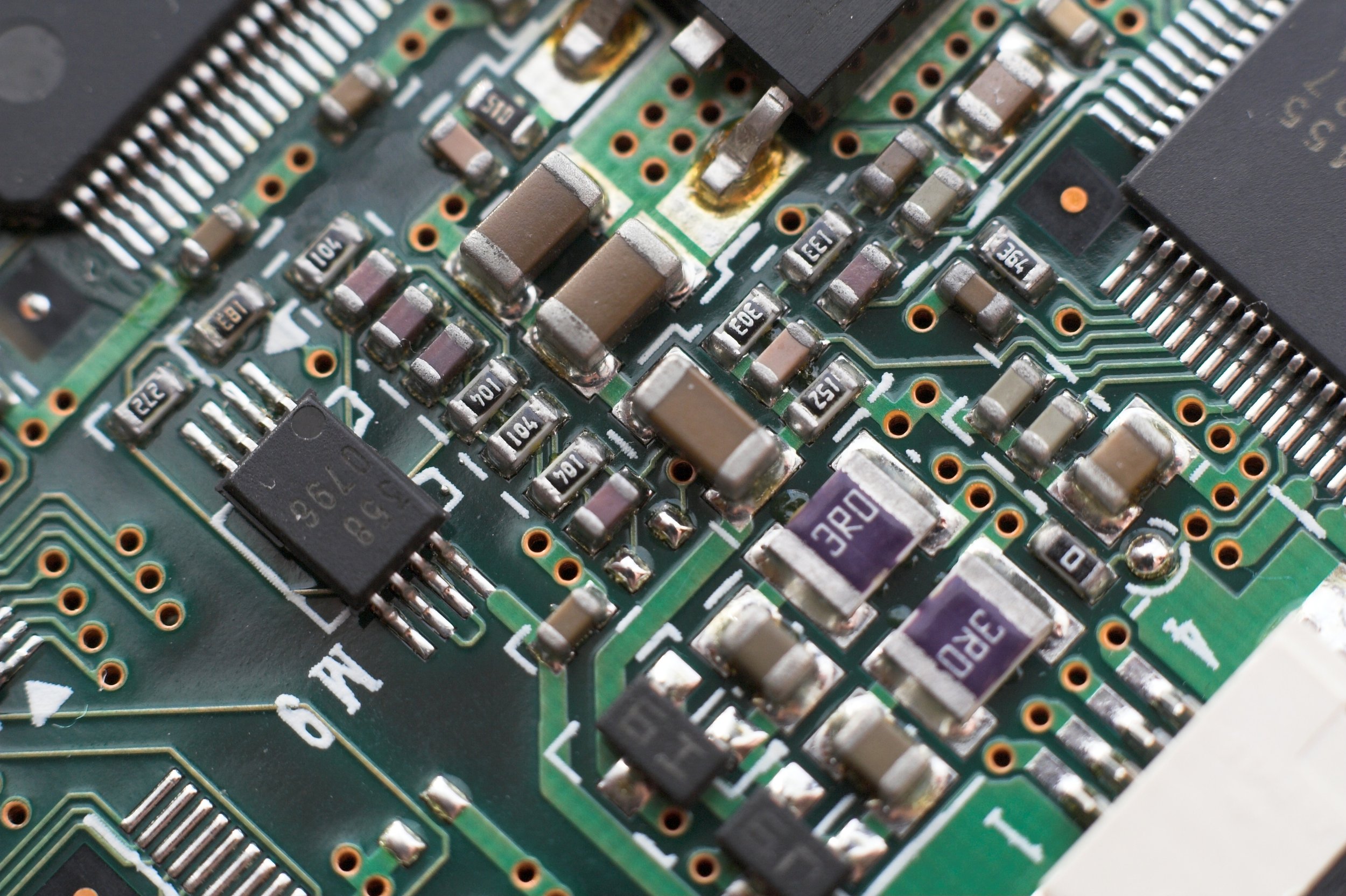

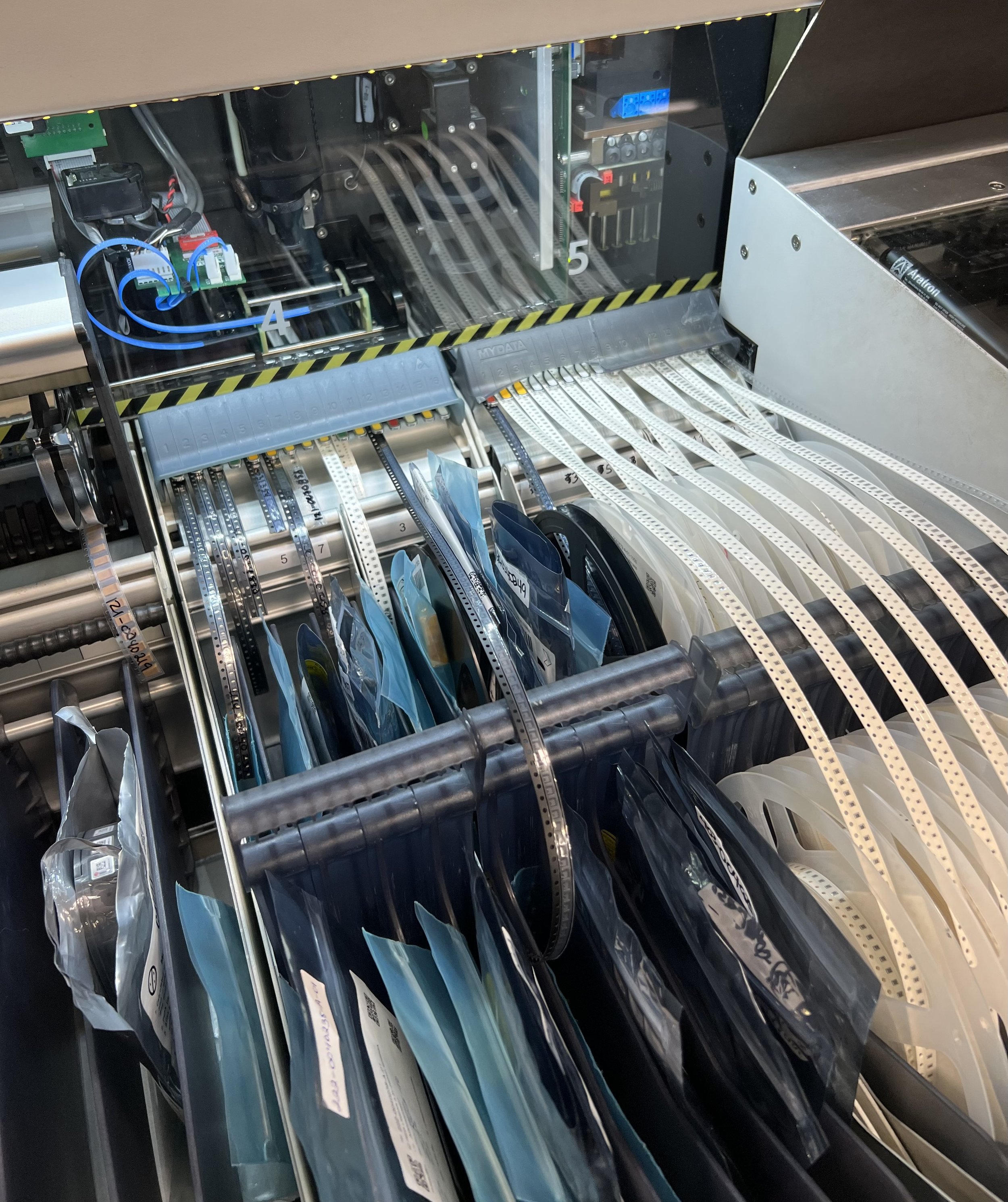

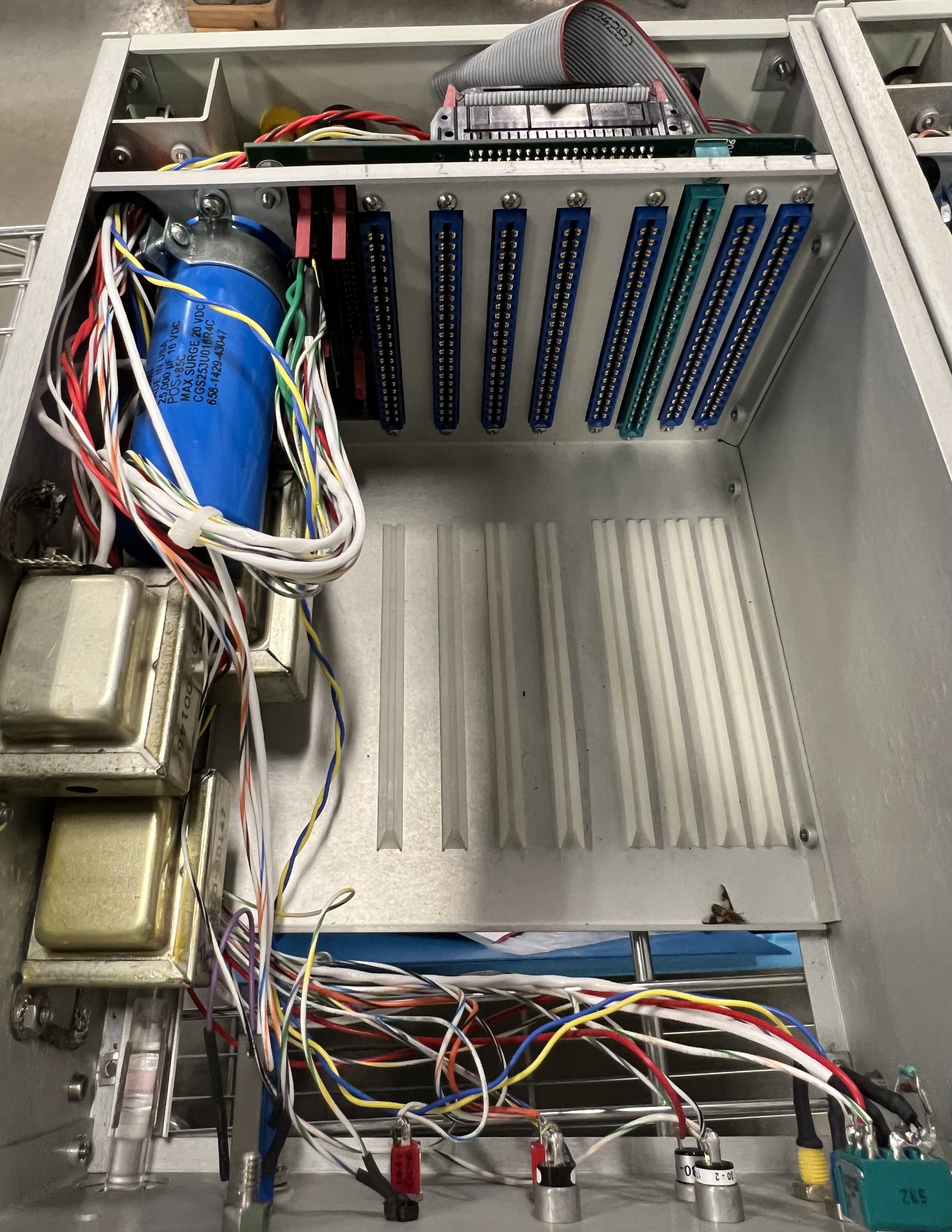

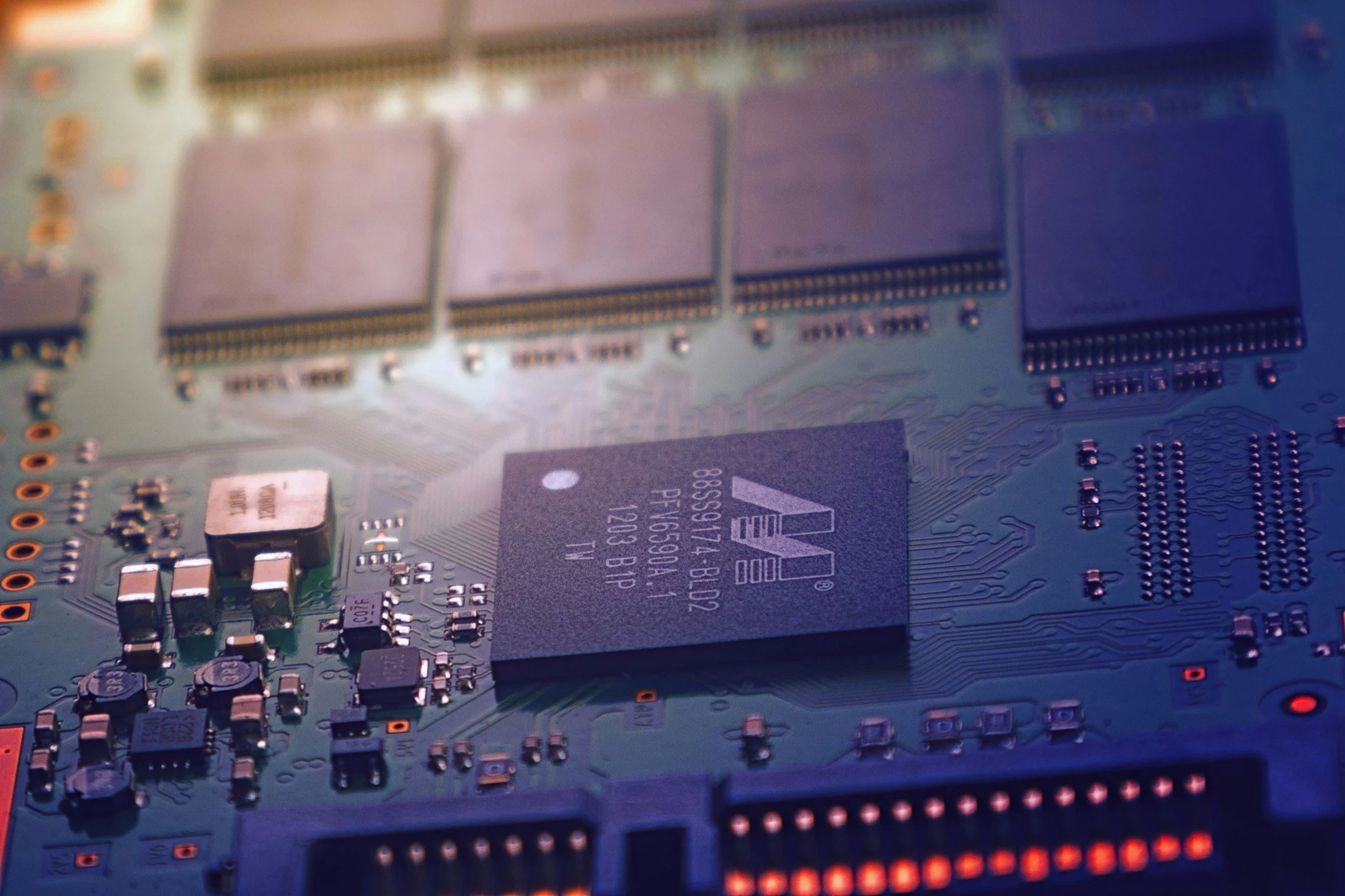

Our PCB assembly services are designed to deliver precision and efficiency, ensuring your electronics are built to the highest standards. From assembling critical components like resistors, capacitors, and switches to affixing them securely onto the circuit board, we provide a complete turn-key solution for your electronic manufacturing needs. With our expertise, you can trust that your final PCB assembly (PCBA) will be accurate, reliable, and ready to perform.

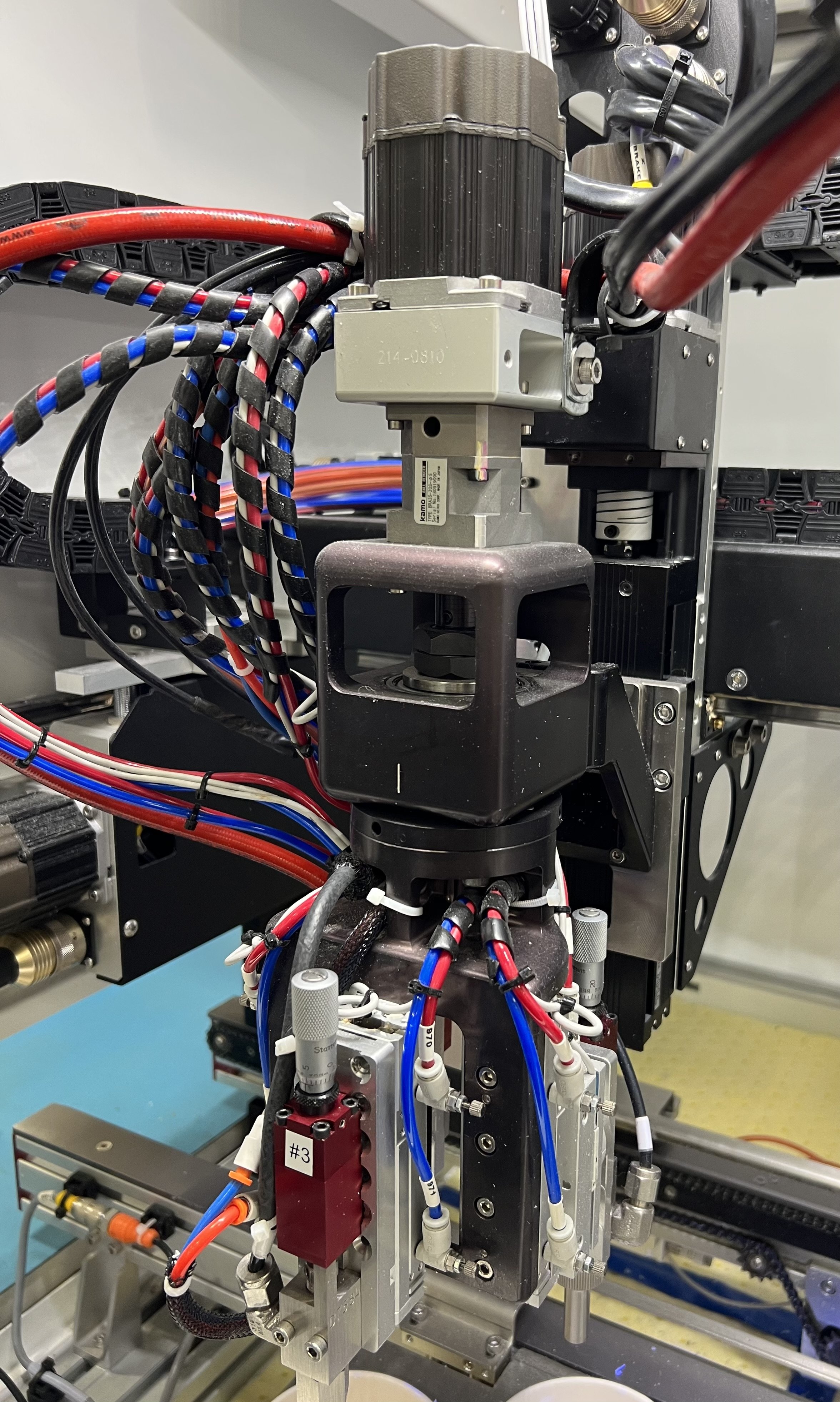

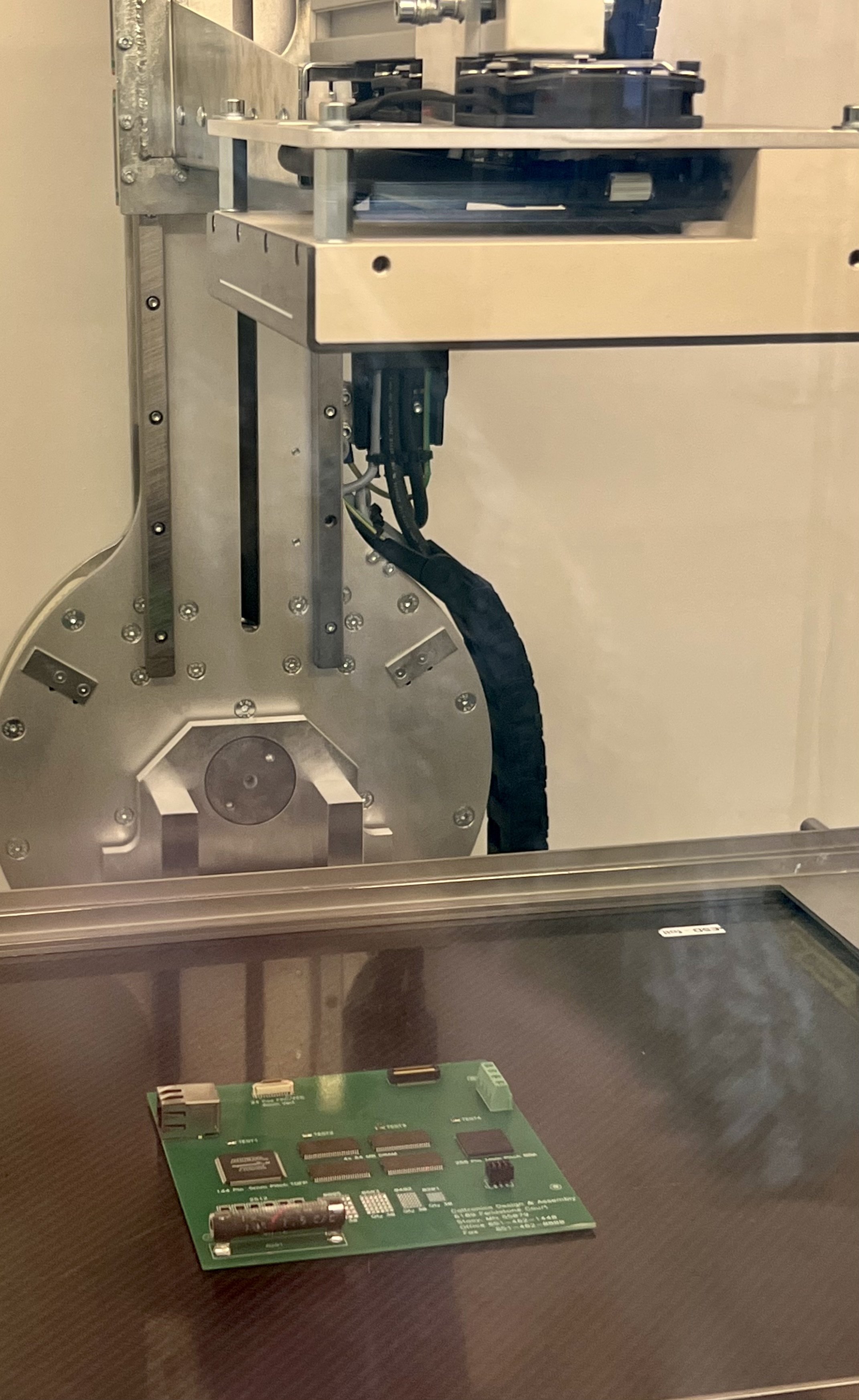

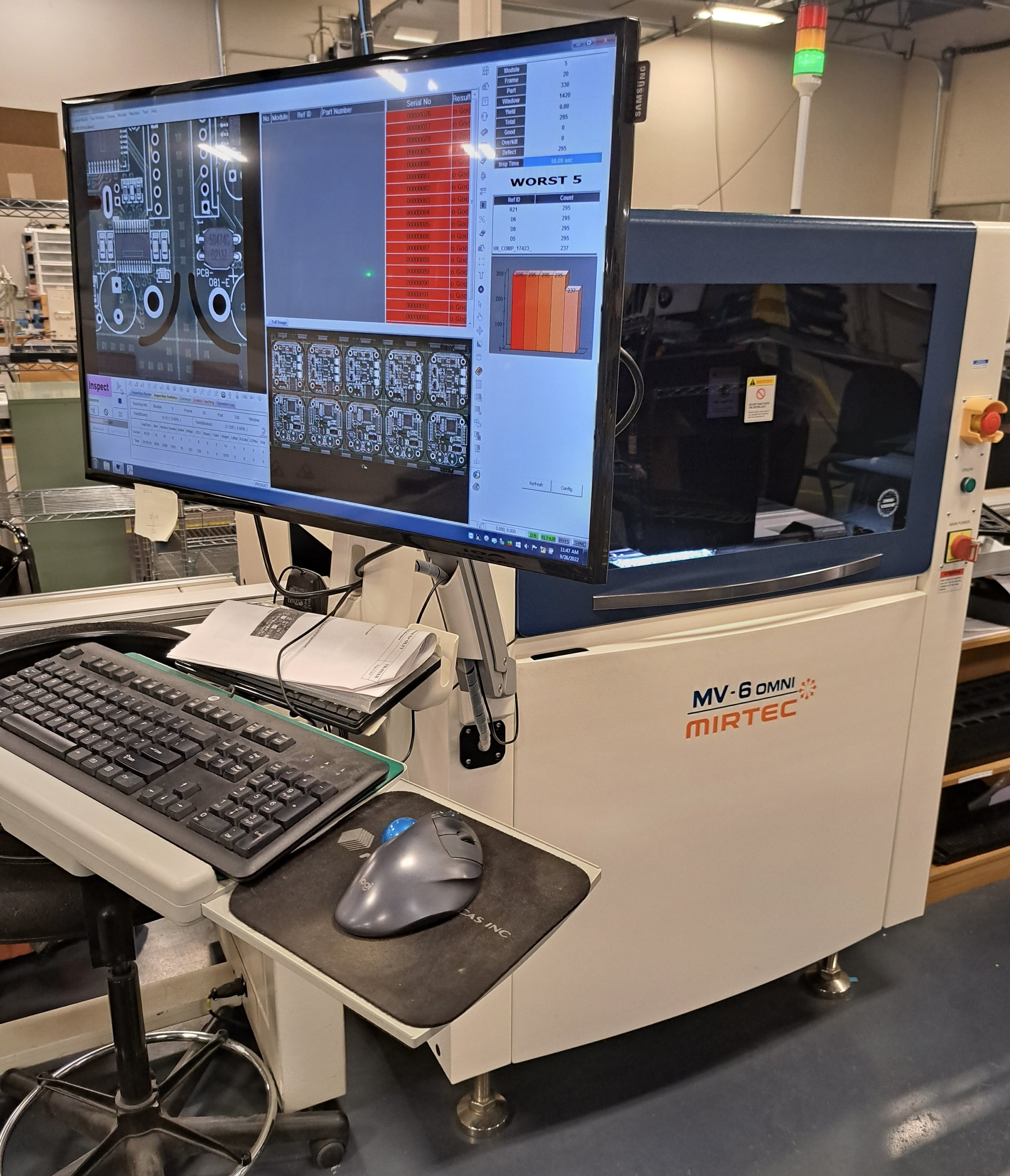

Advanced Quality Assurance with 3D AOI

To ensure flawless results, we use a state-of-the-art 3-D Automated Optical Inspection (AOI) system. This advanced technology meticulously examines the PCBA during the post-assembly stage, allowing our quality team to:

Verify precise component placement.

Measure solder thickness for consistent performance.

By leveraging 3D AOI, we maintain unmatched accuracy and quality in every project.

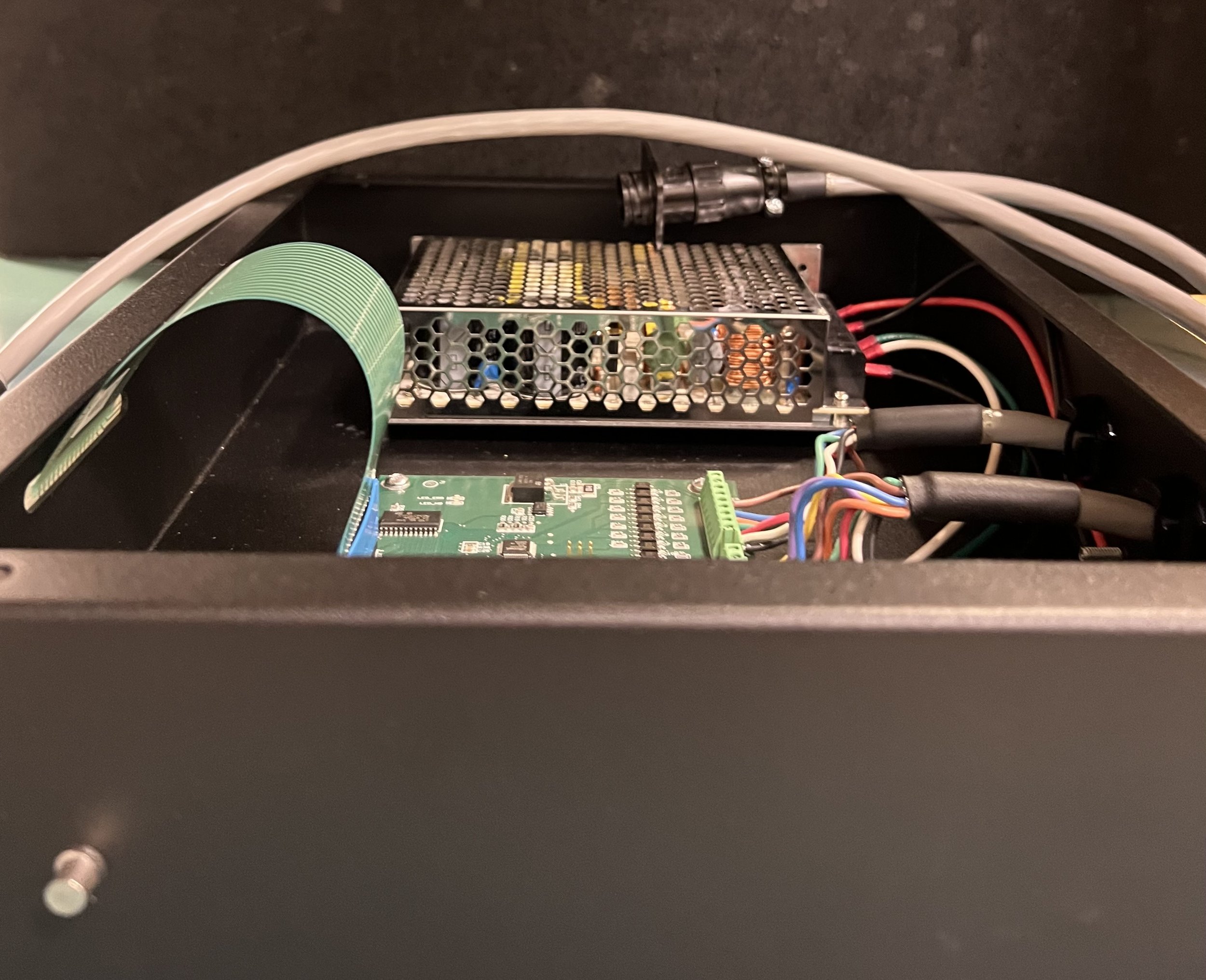

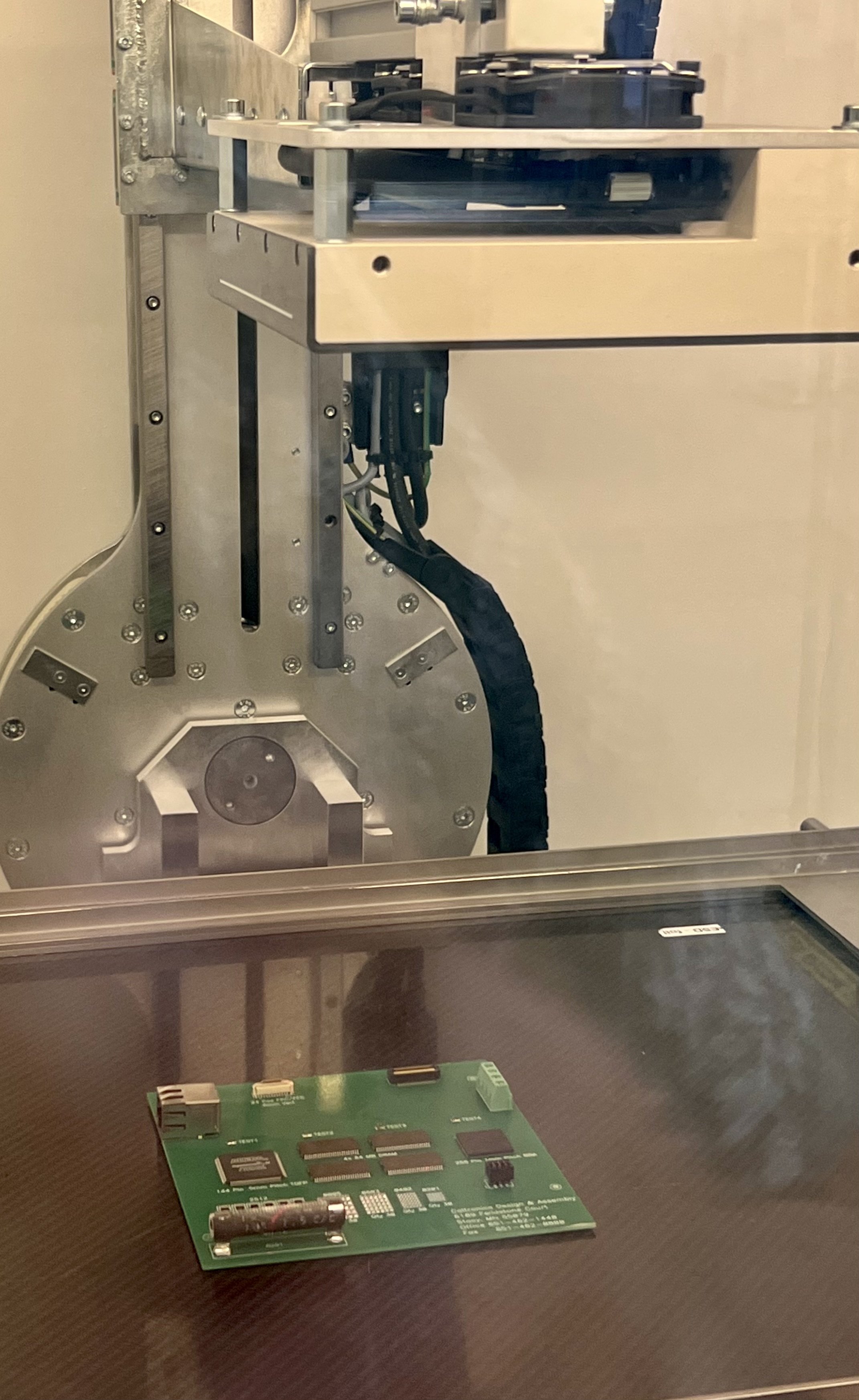

Conformal Coating for PCB Protection

During PCB assembly, our Conformal Coating machine protects boards from hostile environmental conditions by applying a silicon layer to the components and solder to ensure the PCBs can stand up to lower impact ecological risk factors. Caltronics can completely encapsulate the PCBA with customized molds or chambers for extreme environmental risk factors.

Caltronics Design & Assembly is not a bare-board manufacturer, and we partner with many quality companies that are skilled at doing this according to our layouts. When discussing PCBA, we get you to a completed circuit board but might engage with other partners to achieve this.

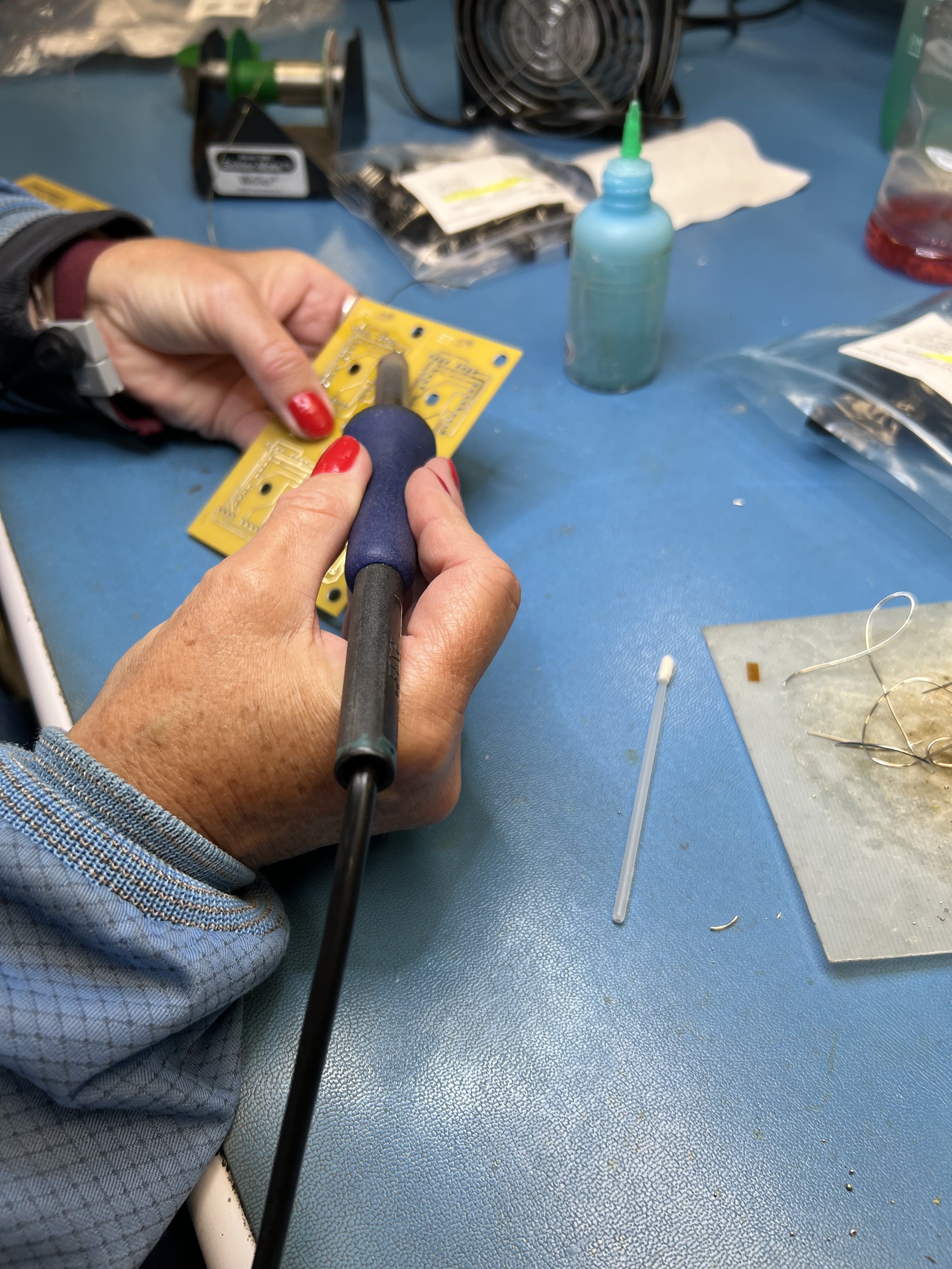

Assembling electronics products from start to finish.

Our in-house team will design and assemble your product from the initial design to the mechanical assembly stage. Our PCB design engineers develop assembly-ready designs that meet each functional requirement.

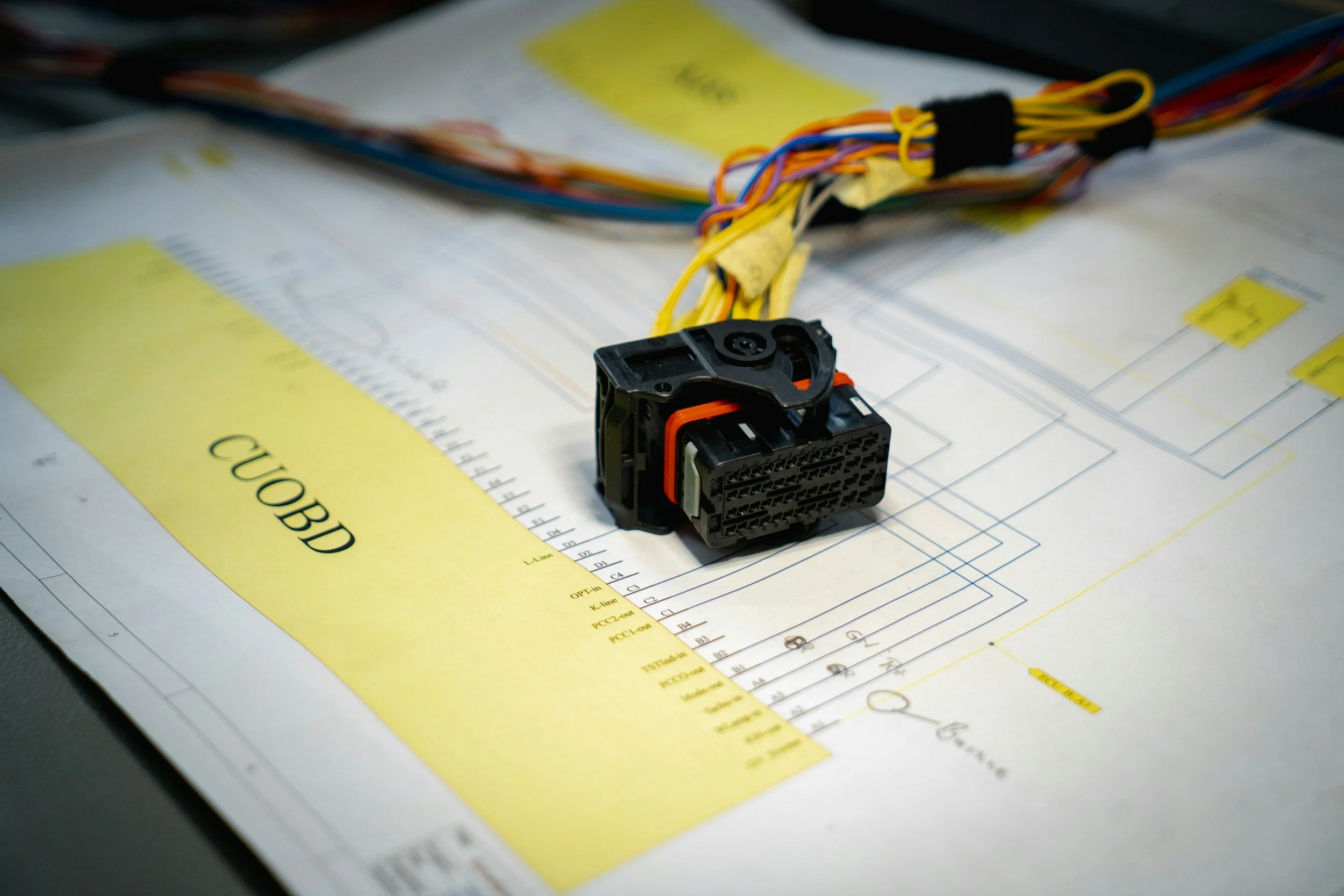

The engineering and testing team can create test fixtures to ensure the product performs as intended. Mechanical assembly provides the final assembly services to put the PCBs into the final product, including attaching wires from the PCB to the unit for proper assembly and functionality.

Electronic and PCB Assembly Services

Our PCB assembly services provide solutions for various industries and types of companies. We have built many printed circuit board assemblies and understand the complexities required for different PCB needs. From prototype PCB manufacturing to small-scale PCB manufacturing to extensive production runs, we will meet your manufacturing demands.

Markets We Serve

Common PCB Assembly Questions

-

The timeline of projects is dependent on delivery time and supply chain manufacturers. Once we have the correct parts in stock, Caltronics’ turnaround time can be as short as one week.

-

Visual Inspection of a Verified First Article, meaning Caltronics matches the prints of the order to confirm the correct build. Then compare the subsequent units against their perfect predecessor.

Caltronics runs a proven first article through our automated optical inspection (AOI) machine that photographs from different angles to confirm that the build is correct according to the design.

By building and running the boards through functional test fixtures to mimic how they would be used for the final PCB assembly.

Your turnkey solution for electronic products and PCB Assembly

Electronic assembly and PCBA Assembly Services require a precise understanding of where each component needs to go, and if done incorrectly, it could result in a poorly functioning product. Our leading experts and advanced technology ensure your product is assembled carefully every time.

Get Started with Caltronics Today

Ready to turn your innovative ideas into reality? Fill out the form below or call us at 651.462.1440 to learn how we can assist you in achieving your goals.

Additional PCB Assembly & Design Services