PCB Design for Manufacturing (DFM)

PCBs Designed for Manufacturing from the Start

PCB Design for Manufacturing from Start to Finish

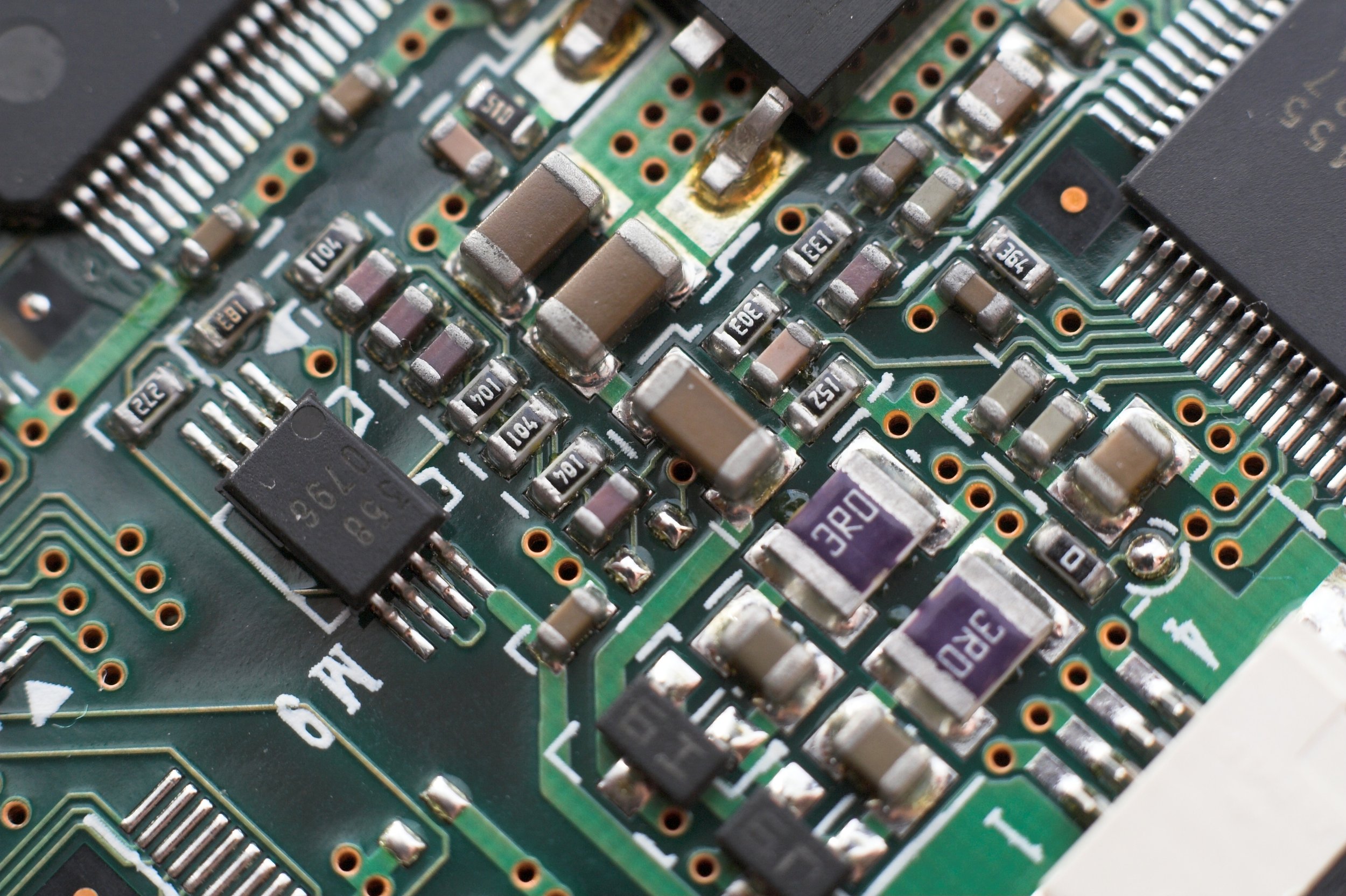

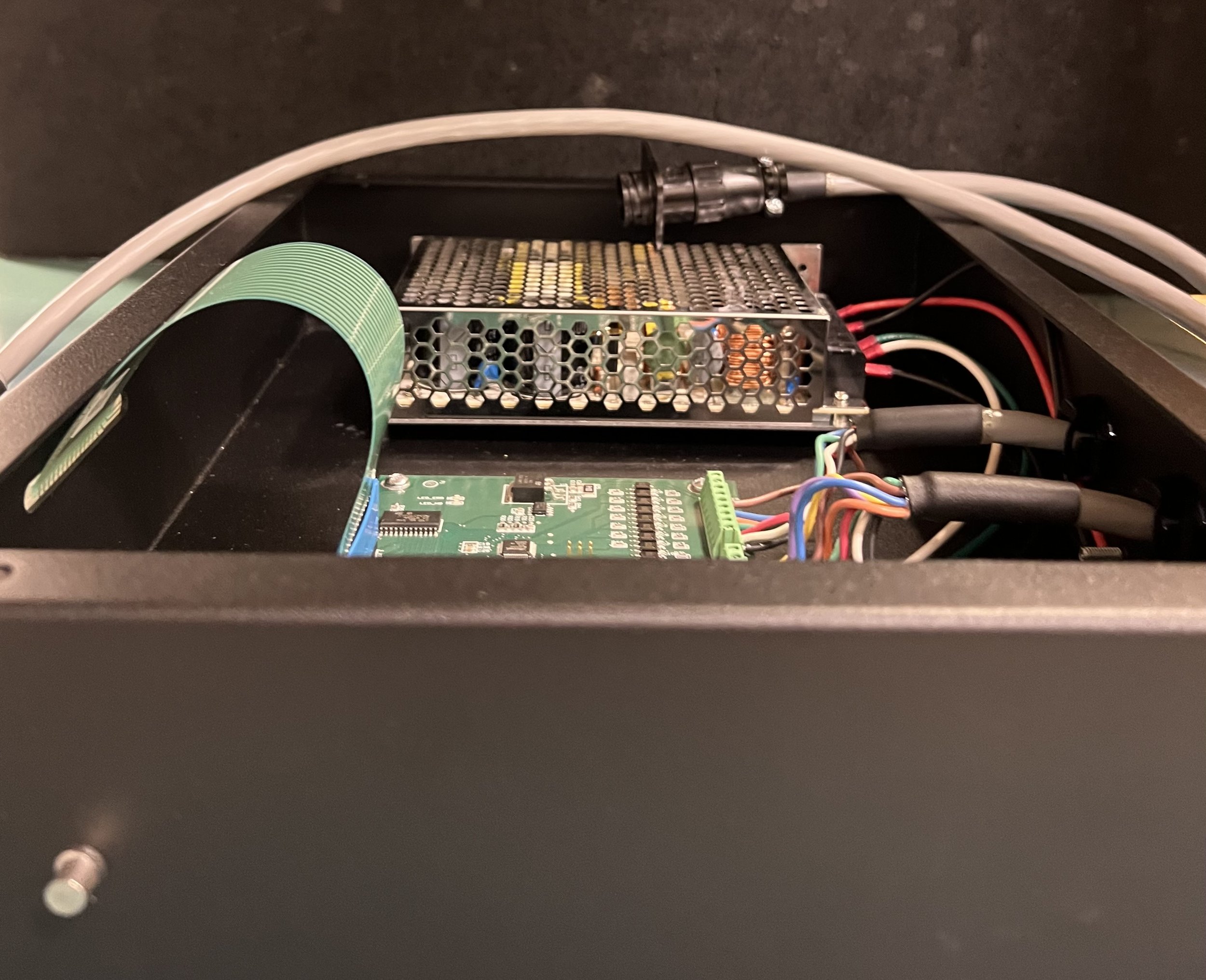

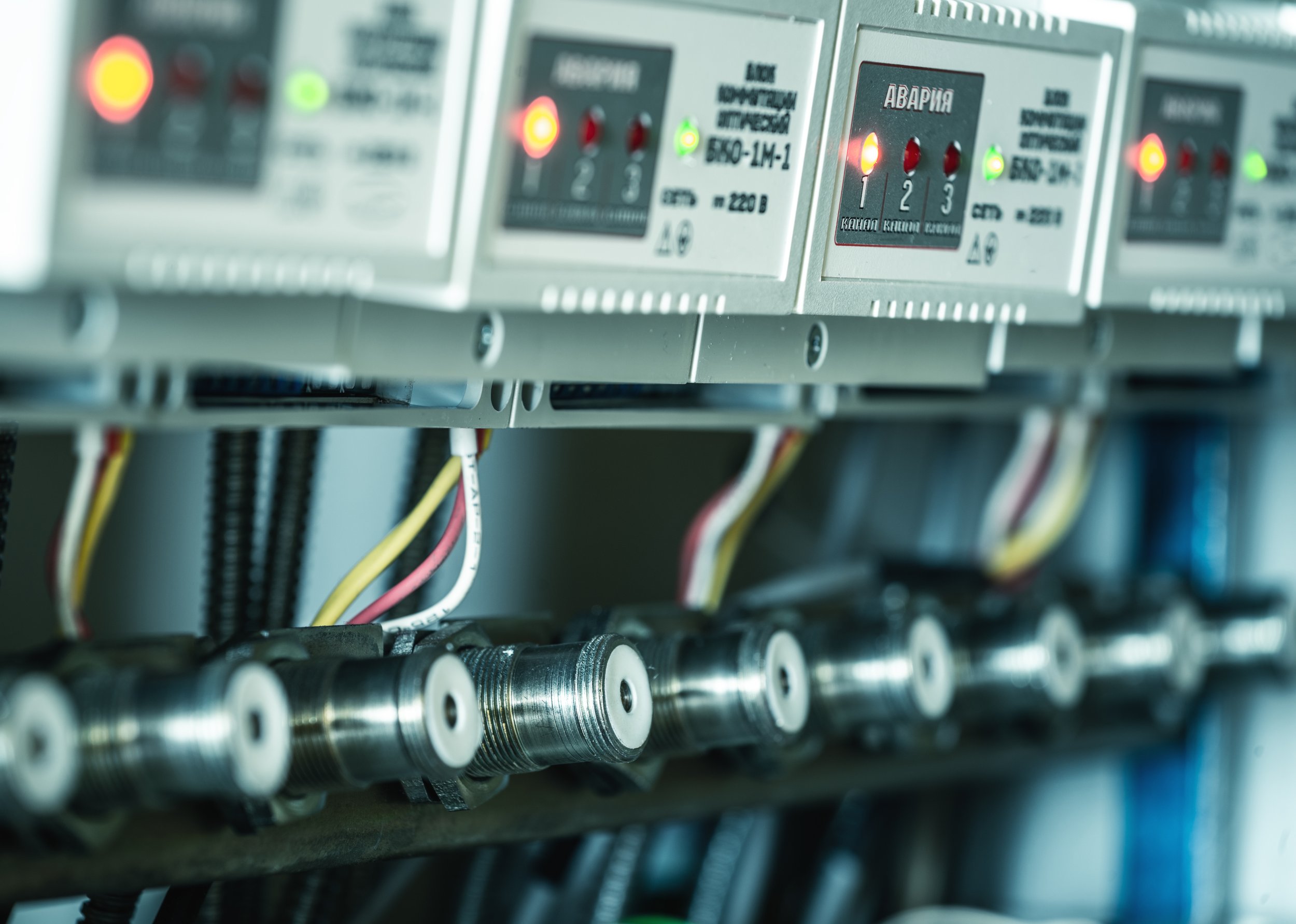

PCB design for manufacturing (DFM) incorporates the requirements and considerations for manufacturing the physical PCB. While PCB schematics may be designed using software on the computer, there are essential components that cannot always be replicated on a computer design

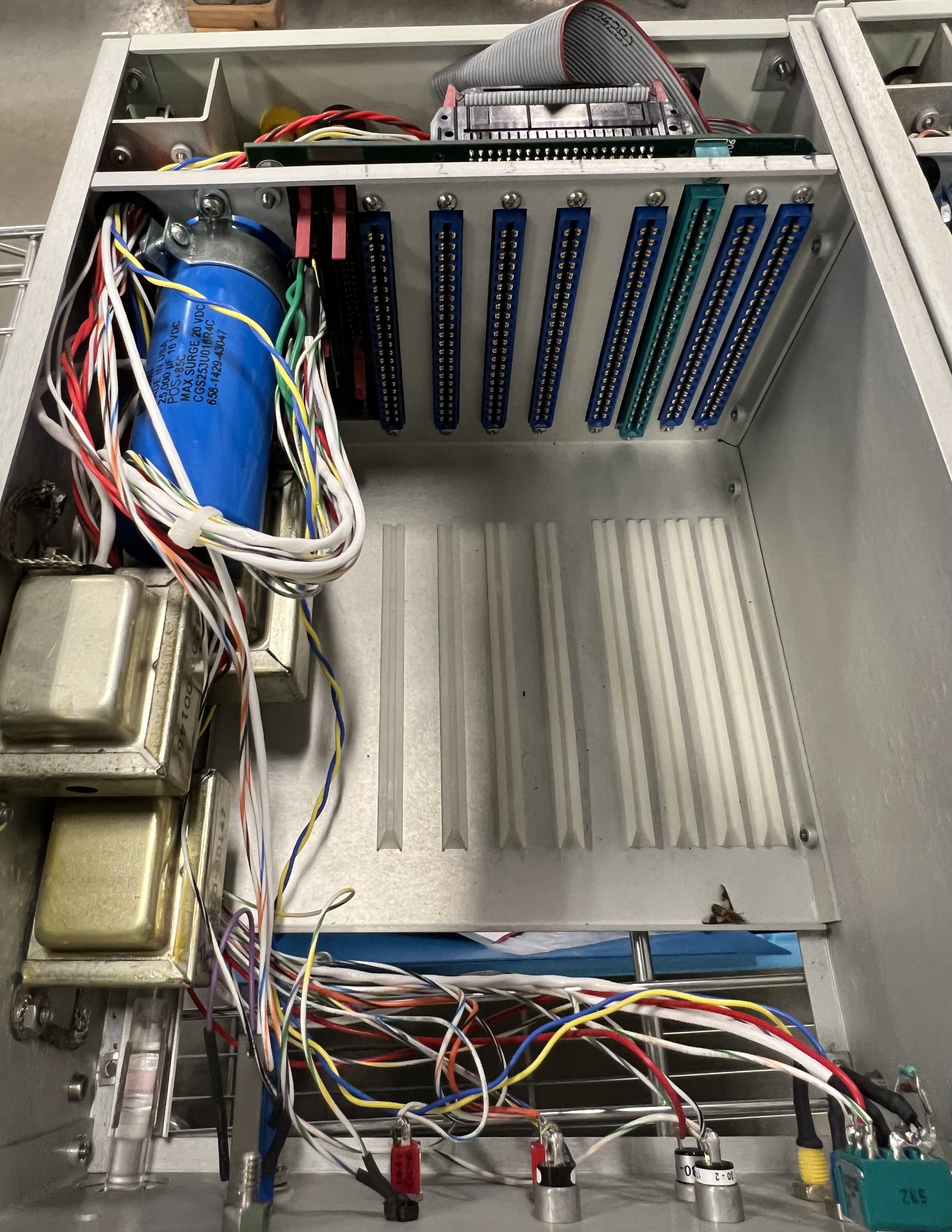

We evaluate the device constraints and the process for assembly. We ensure we are staying ahead of industry standards, and our design for manufacturing services considers the stipulations that go into the manufacturing process to make a functional device every time.

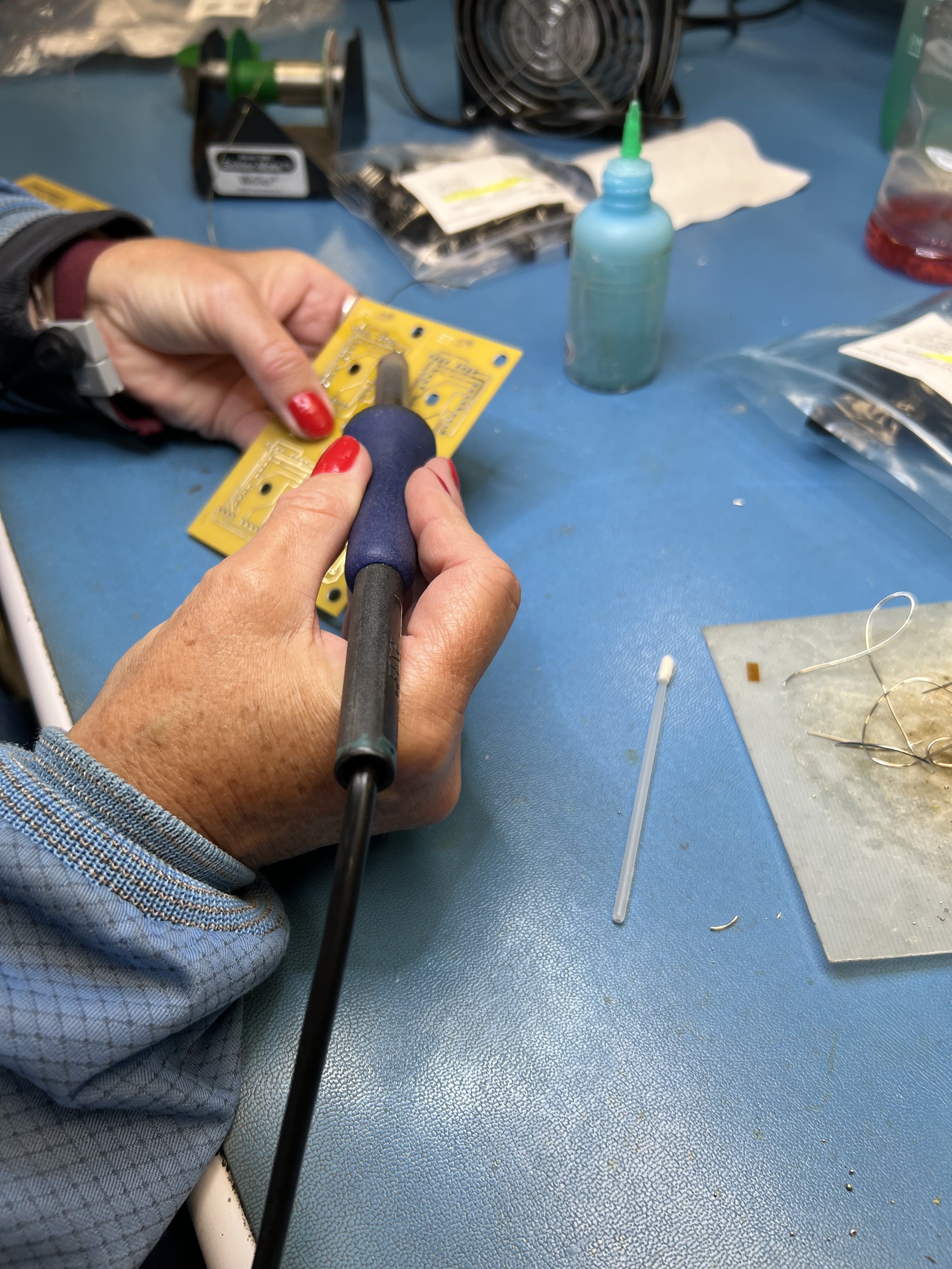

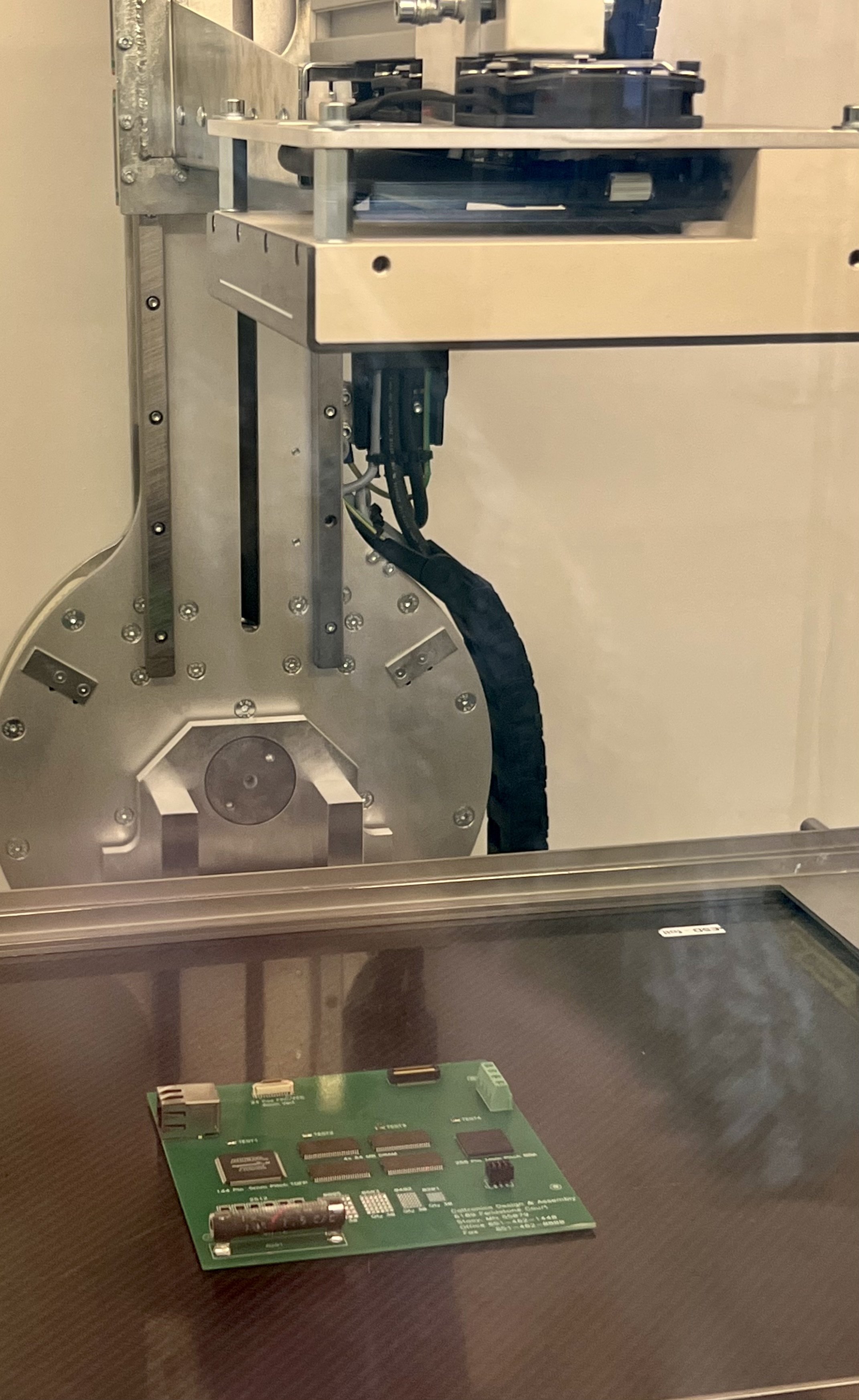

Not only are we your engineering or manufacturing firm, we are your partner from the start of the project to the finish. We do more than just receive design files; our electrical engineers on staff are the ones developing the original PCB designs and overseeing them during the assembly process.

Our electrical engineers have decades of experience designing PCBs for manufacturing, so they understand the considerations that go into manufacturing the PCB and assembling the product. Since Caltronics offers each phase of the PCB production process in-house, your project is expertly handled from start to finish.

PCB Design for Manufacturing (DFM) Services Built with Cost-Efficiency in Mind

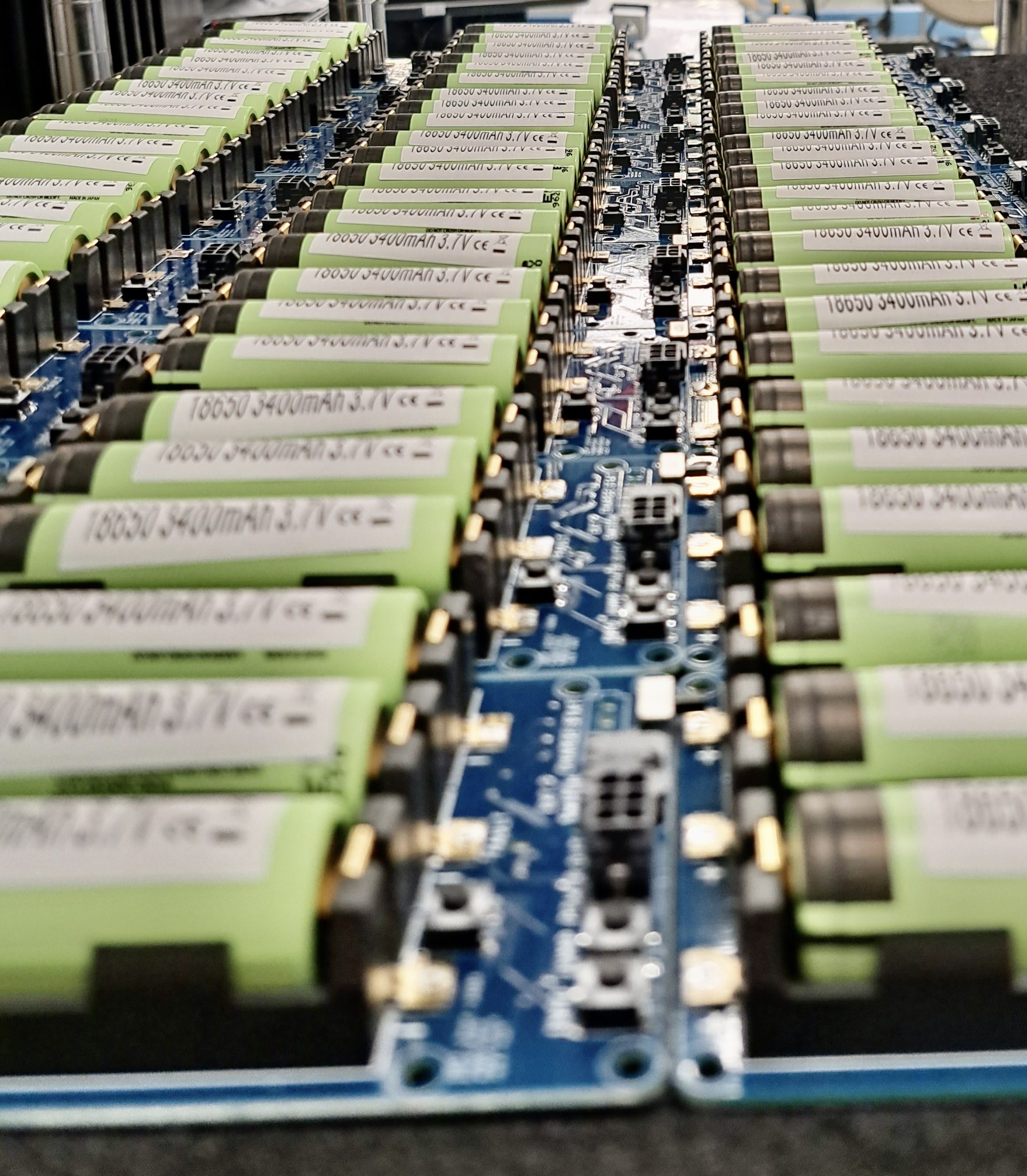

We are a full-service company that specializes in

PCB Design

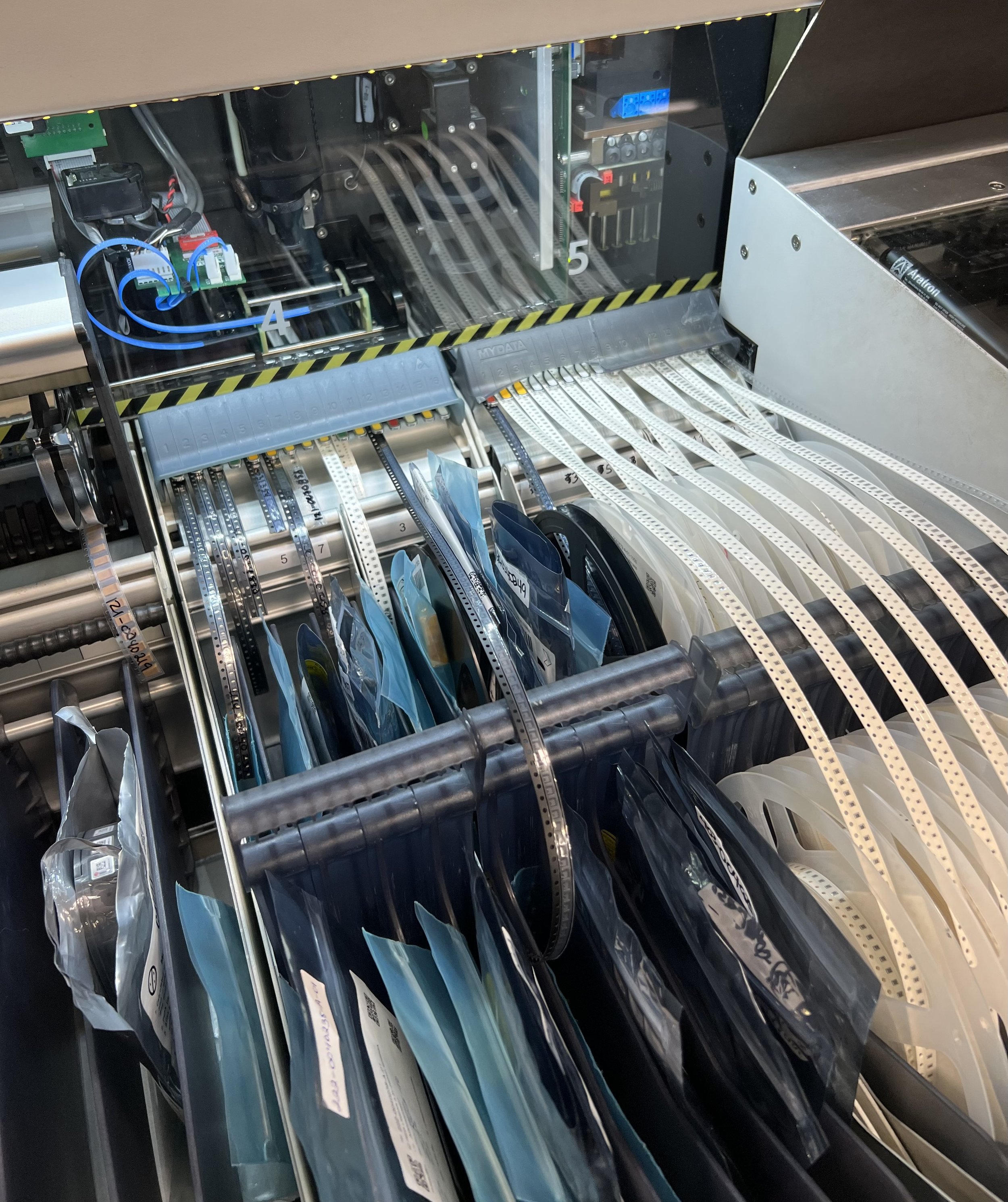

Manufacturing

Assembly

These three factors allow us to understand the full scope of production costs and limit useless spending. When we are designing the PCBs, we consider the production processes, component costs, and supplier agreements. We provide insight to optimize each design for manufacturing by looking at unique ways that will both cut costs and accomplish the goals of the design.

Industries We Work In

Common DFM Questions

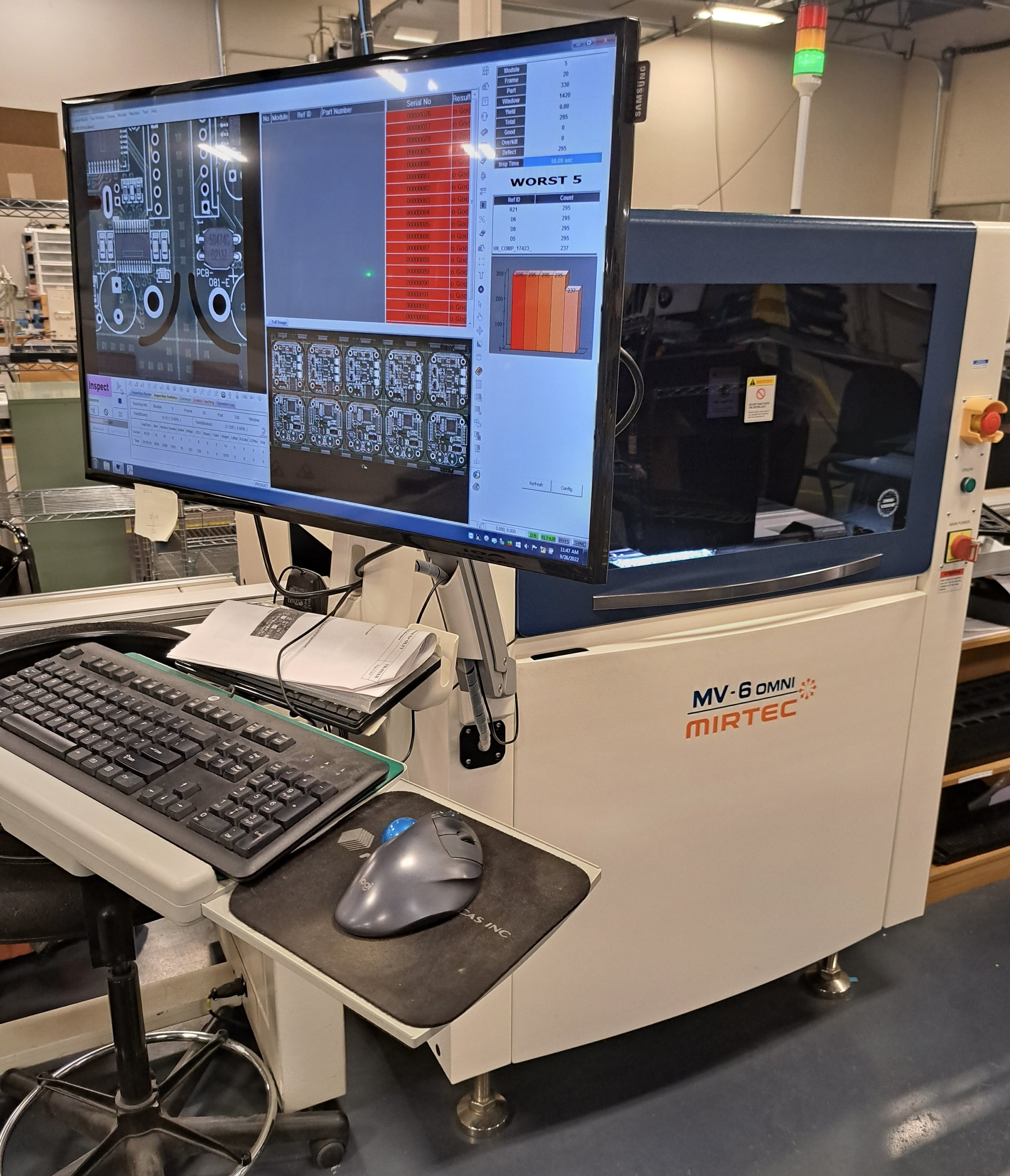

Why are DFM Services essential?

What are common considerations that go into the DFM process?

PCB designs only created on a computer can miss simple functions vital to the product's final goal. By designing for manufacturing, we can better examine how the product will work compared to a strong estimate.

Water-Resistance

Hostile Environments

Radio Wave Interferences

External Trigger Barriers

Spatial and Structural Awareness

Start Your Project with Manufacturing in Mind

Our designs exceed the limitations of the computer screen and include the necessary components needed for manufacturing.

We develop methods equipped with the specifications needed to streamline your product from design to manufacturing.